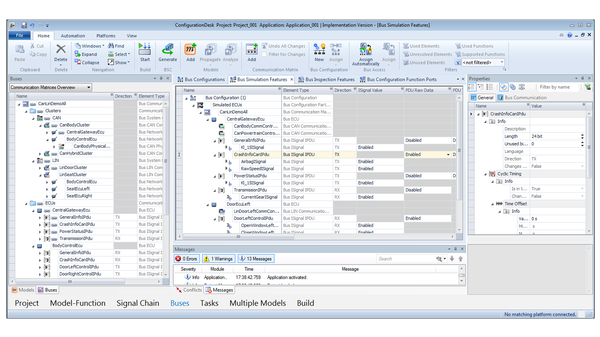

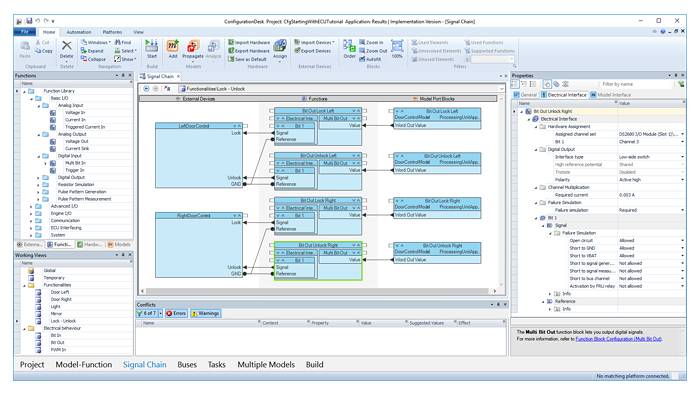

HIL and RCP just one step away: With ConfigurationDesk, you quickly achieve precise results for your hardware-in-the-loop and rapid prototyping scenarios.

What is ConfigurationDesk?

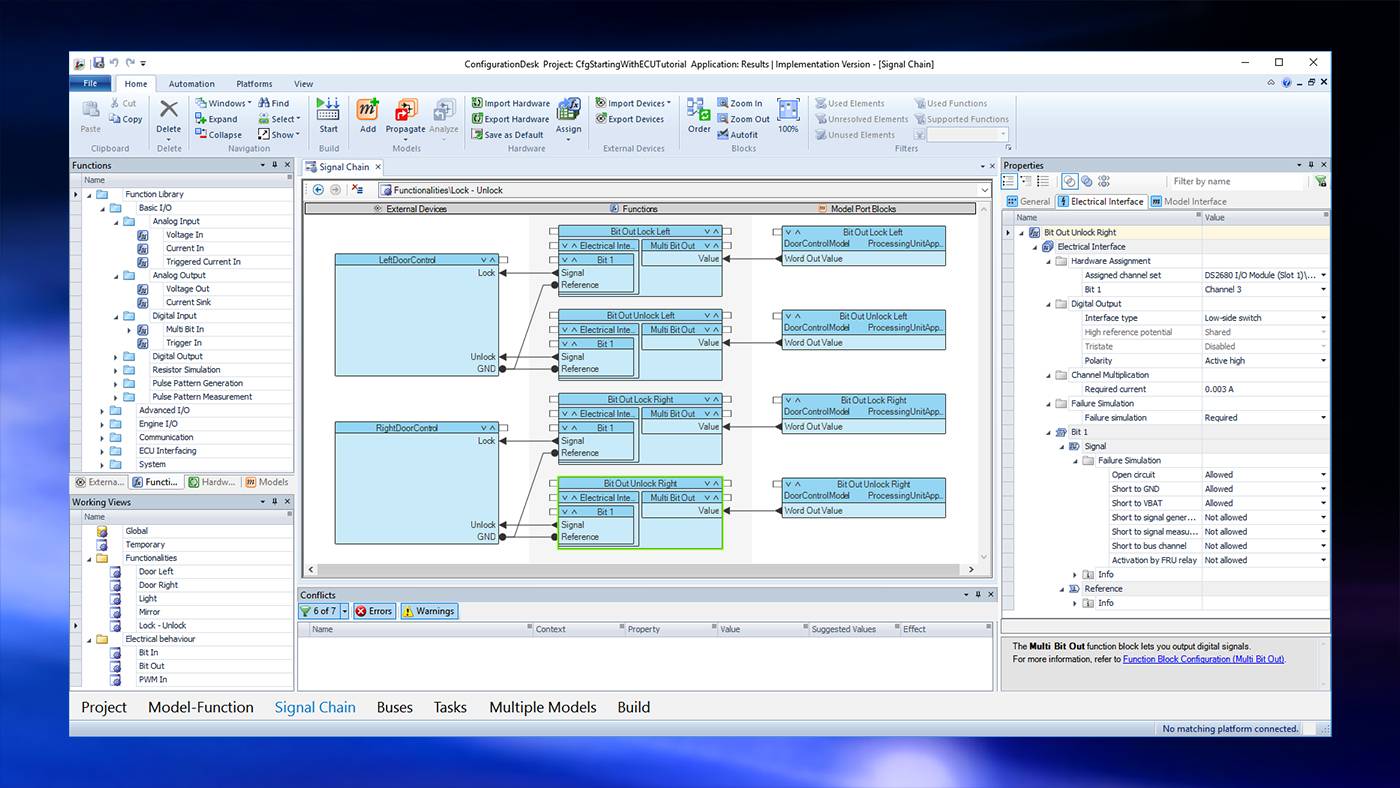

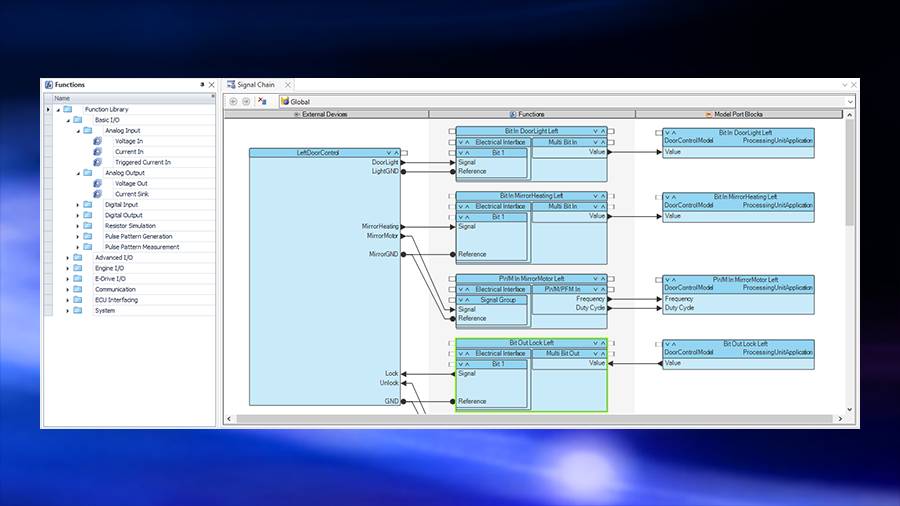

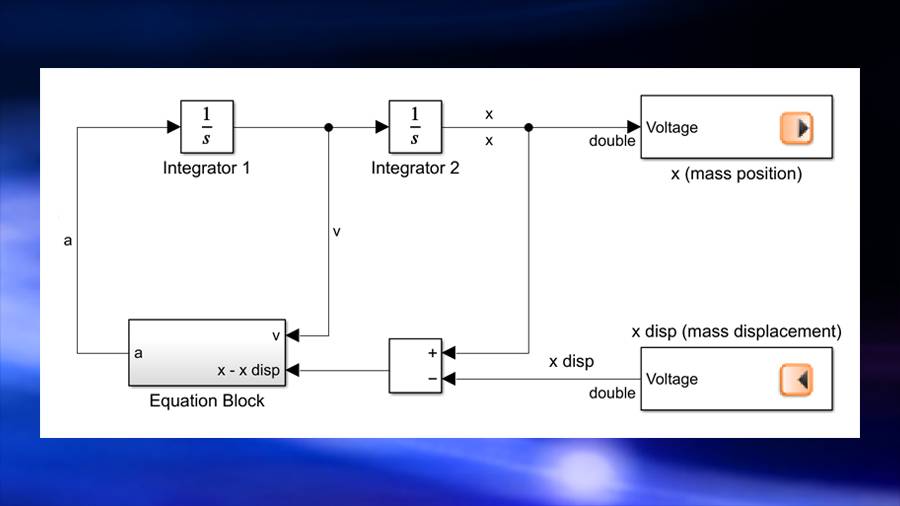

With ConfigurationDesk, you can graphically connect your Simulink models and Functional Mock-Up Units (FMUs) to input/output channels of dSPACE real-time simulation systems.

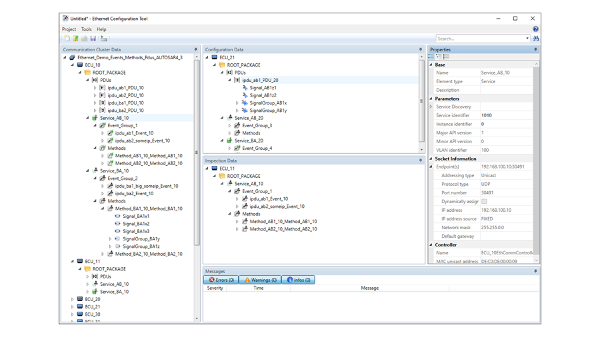

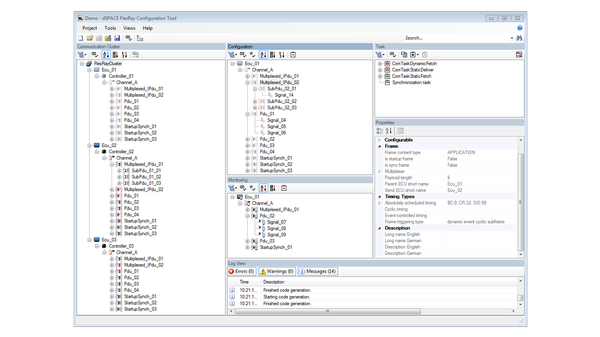

With the versatile capabilities of the supported SCALEXIO, MicroAutoBox III, and MicroLabBox II systems as well as ConfigurationDesk's flexible configuration, you can connect the models to any electrical device or bus communication (Ethernet, CAN, LIN, FlexRay).

You can integrate multiple models to a powerful simulation, flexibly distributed on the cores and processing units of the real-time system. If needed, you can precisely configure the timing properties of the simulation.

You can optionally define and document external devices, such as ECUs, electrical devices, and loads, including their signal properties.

Fields of Operation

- Hardware-in-the-loop testing (HIL)

- Rapid control prototyping (RCP)

- Bus and network communication

- Simulation modelling

Industries & Applications

- Automotive (software-defined vehicles, autonomous driving, e-mobility and further)

- Aerospace

- Electric power industry

- Rail industry

- ... and many more

Easy to Use and Timesaving

ConfigurationDesk provides graphical, guided, and interactive configuration, tailored both for HIL and RCP workflows. It checks, optimizes, and implements everything for you. It gives you a clear and easily documented overview of your whole real-time application's configuration.

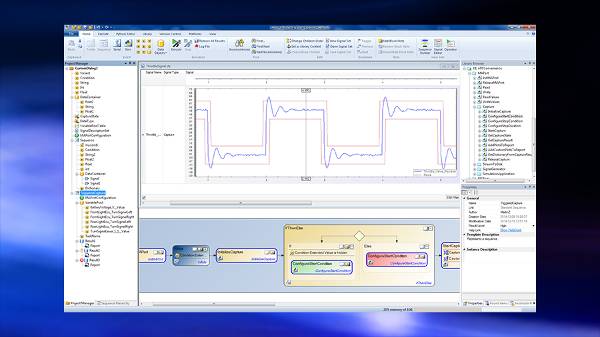

Interactive Simulink Workflow

Together with its partner product Model Interface Package for Simulink (MIPS), ConfigurationDesk facilitates smooth interaction with Simulink that allows you to easily jump from one tool to the other. The workflow supports the insertion and synchronization of data interfaces in the model, matching the hardware channels in ConfigurationDesk with a single click.

For this purpose, MIPS provides model port blocks to connect hardware channels or communicate with other models. In ConfigurationDesk, these connections stay robust and are preserved even when Simulink model structures change.

MIPS provides extensive support for modeling and code generation capabilities of Simulink and Simulink Coder. Furthermore, MIPS generates information for dSPACE experimentation tools like ControlDesk to provide them comprehensive access to Simulink model parameters and signals during real-time simulation.

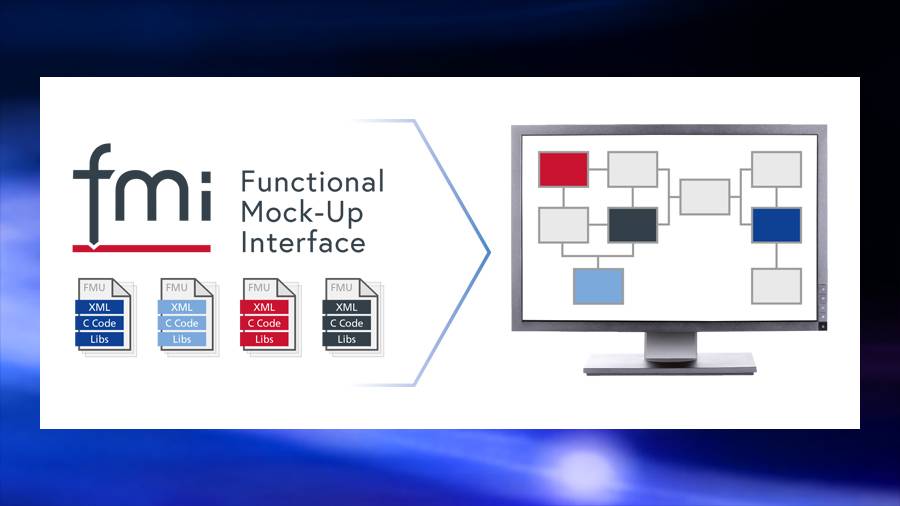

FMI/FMU Standard Supported

ConfigurationDesk supports Functional Mock-Up Units (FMUs) with co-simulation interface according to FMI 2.0.x and FMI 3.0 standards. Through its support for FMUs both in source code and Linux-compatible binary form, the wide world of modelling tools exporting FMUs is open to you.

Simple Integration

After importing a model, e.g., a Simulink model or a Functional Mock-Up Unit (FMU), the workflow for connecting models and configuring real-time execution is fully the same. This makes it easier for you to integrate models from different tools in an arbitrary mixture to suit your use case.

Modifying the deployment of the models on the cores and processing units is possible without impacting the connections that you already have configured.

Connections are possible even when data types and sizes of signals differ. ConfigurationDesk generates code that adapts both sides adequately.

Easy Reuse of Application Parts and Models

ConfigurationDesk keeps the hardware configuration separated from the models. Thus, models can be reused in different applications and on different hardware without needing any modifications. Furthermore, the exchange of a model against a variant is just one click.

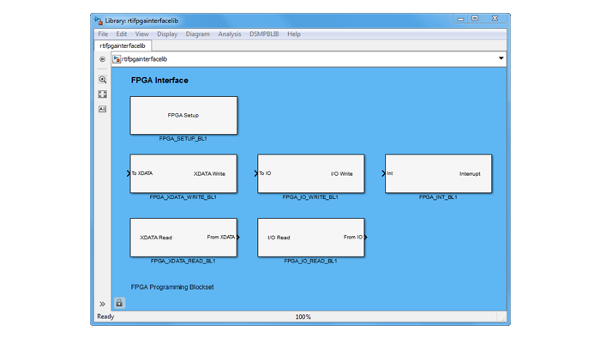

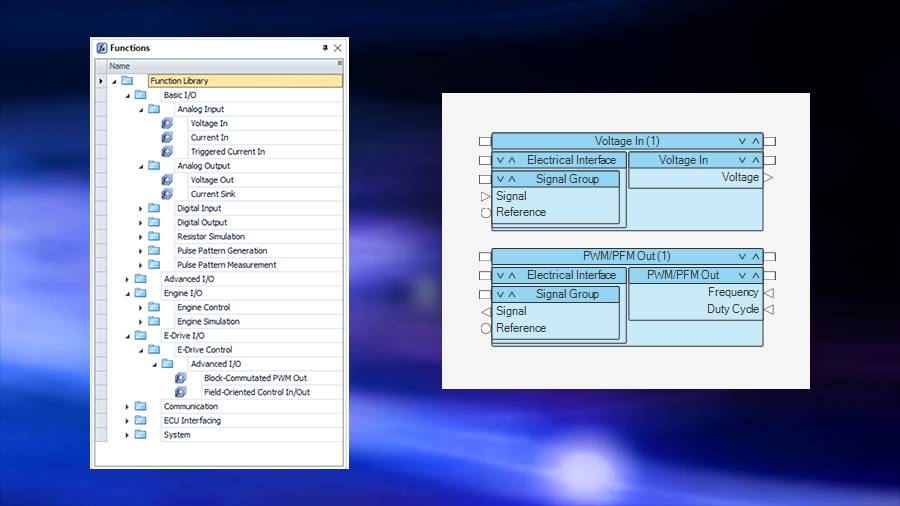

Vast I/O Function Library

To connect any electrical device, ConfigurationDesk provides many I/O function types:

- Analog and digital input/output

- Pulse pattern and waveform generation/measurement

- Analog signal and sensor signal capture

- Combustion engine I/O

- E-drive I/O

- Battery simulation

- Bus communication

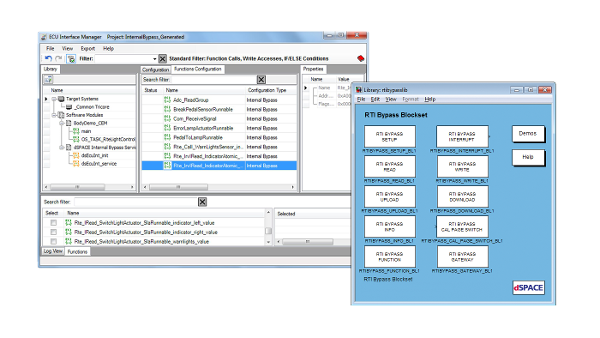

- ECU interfacing

- Functional safety

and many more.

Intellectual Property Protection Enabled

When working with partners, exchanging models with IP protection is a crucial point. With its support for so-called model containers that can contain the model implementation in compiled (binary) form and without source code, ConfigurationDesk perfectly supports these needs. This is available for Simulink models, Functional Mock-Up Units and bus simulation. Check out our IP Protection Guideline here.

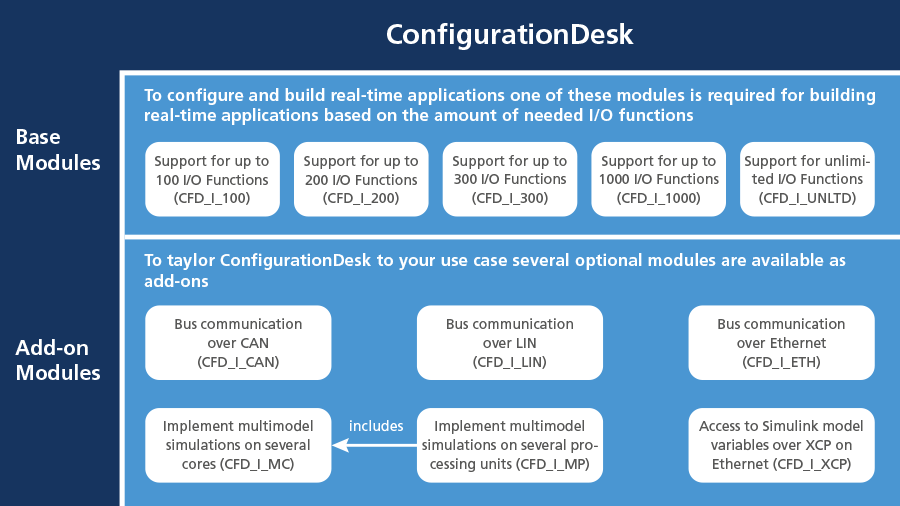

ConfigurationDesk Modules

To work with ConfigurationDesk you can choose between different base modules and further optional modules.

Required Products

You need one of these hardware solutions to be able to work productively with ConfigurationDesk.

The hardware solution depends on your application. We will be happy to advise you.

Optional Products

Depending on your use case, the following products are the perfect extension for your ConfigurationDesk-based HIL or RCP toolchain.

Support for ConfigurationDesk Users

Links to detailed technical information and customer service. Access may require registration.