ControlDesk是什么?

ControlDesk将多个专用工具的功能集于一身。它可以访问仿真平台以及所连接的总线系统,还可以在ECU上完成测量、校准和诊断(例如通过标准化ASAM接口)。其灵活的模块化结构拥有高度可扩展性,可满足特定应用实例的要求。在处理、所需的培训量、需要的计算能力和成本方面它将给您带来明显的优势。

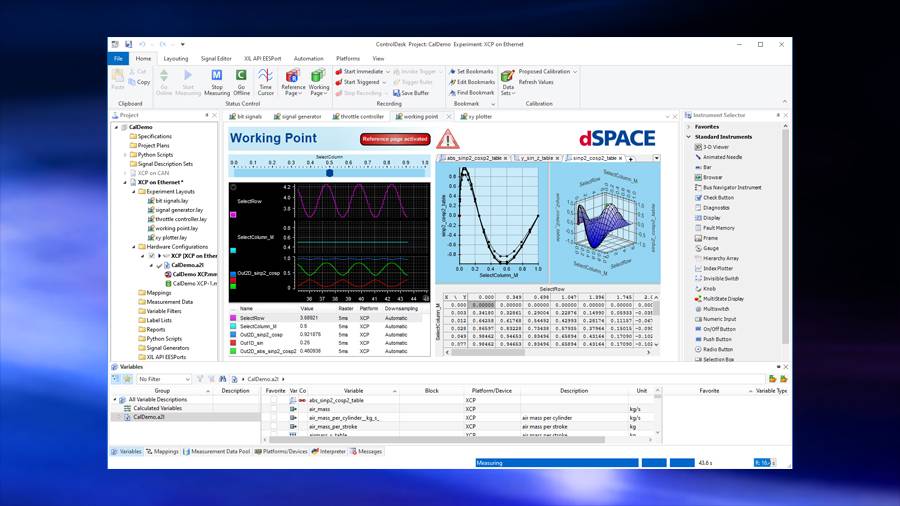

- 集成的ECU校准、测量和诊断访问(CCP、XCP、ODX)

- 在ECU、RCP和HIL平台以及总线系统上同步数据采集

- 强大的布局创建、仪表、测量和后处理(ASAM MDF)

- 支持整个dSPACE虚拟验证工具链

应用领域

ControlDesk适合各种用例,例如:

- 快速控制原型开发(RCP)(全通、旁通)

- 硬件在环(HIL)仿真

- ECU 测试、校准和诊断

- 访问车辆总线系统(CAN、CAN FD、LIN 和 Ethernet)

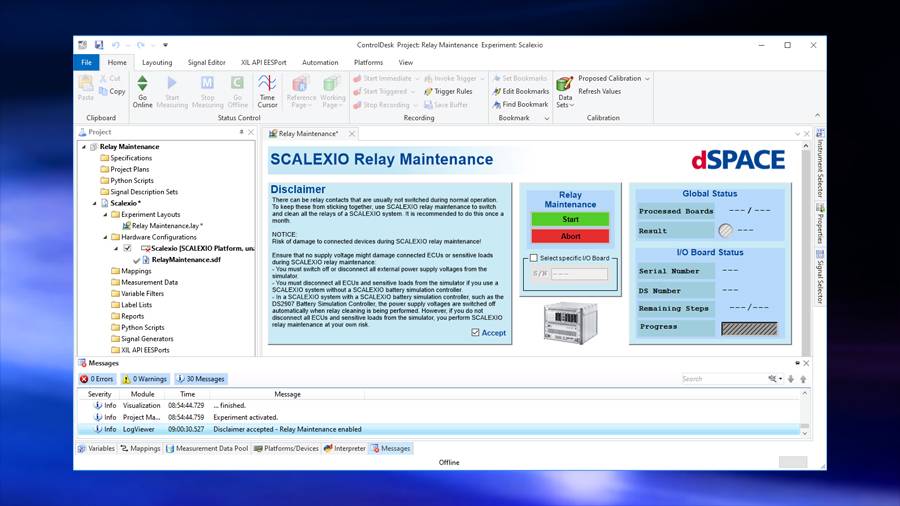

- 使用dSPACE产品VEOS和SCALEXIO进行虚拟验证

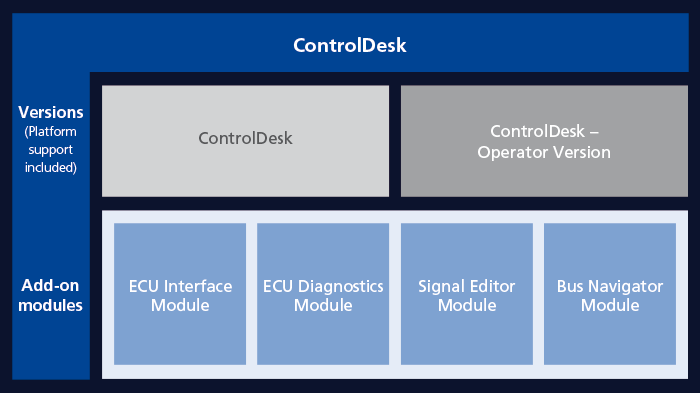

ControlDesk — 主版本

这是ControlDesk的主版本:它适用于创建和运行实验,以及访问dSPACE实时硬件和VEOS软件。其功能可以通过可选的软件模块进行扩展。

- 使用同一种工具可以实现快速控制原型开发、HIL仿真、离线仿真、ECU校准及诊断

- 容易创建布局和仪表

- 对所有数据源进行同步测量

- 项目与实验综合管理

- 测量数据综合管理(ASAM MDF 4.1)

- 兼容多种ASAM标准(例如SAM MDF、XCP、CCP、ASAP2、ODX)

- 强大的工具自动化能力,可针对特定用户进行扩展以及获得最佳的过程集成

- 操作员模式(防止您的项目和实验遭受未经授权的更改)

- 支持dSPACE VEOS和SCALEXIO的虚拟验证测试场景

- 所有dSPACE实时硬件平台的内置访问权限

- 支持符合ASAM XIL标准的变量映射,以解耦实验和仿真模型的变量

ControlDesk — 操作员版本

此版本的ControlDesk提供运行现有实验的功能子集。功能范围可以通过可选的软件模块进行扩展。

- 使用ASAM XIL API MAPort服务器访问第三方测试台架和其他硬件的内置访问权限

- 使用ASAM MCD-3标准工具实现快速控制原型开发、HIL仿真、离线仿真、ECU校准及诊断的内置自动化功能

- 用于使用通过标准ControlDesk版本创建的项目和实验数据

- 防止更改和创建项目和实验

-

所有dSPACE实时硬件平台的内置访问权限

请注意:此版本不支持MCD-3自动化功能。

模块

ECU接口模块

这个可选的ControlDesk软件模块用于对电子控制单元(ECU)进行校准和测量访问。它还可用于对SIL测试场景中使用的虚拟ECU(V-ECU)进行校准和测量访问。

- 支持AUD、NBD、JTAG/Nexus、JTAG/OCDS和JTAG/SDI

- 支持CCP(CAN校准协议)

- 支持CAN上的XCP、CAN FD上的XCP、Ethernet2上的XCP)(TCP/IP和UDP/IP)

- 支持ASAM A2L 1.7中指定的结构化数类型

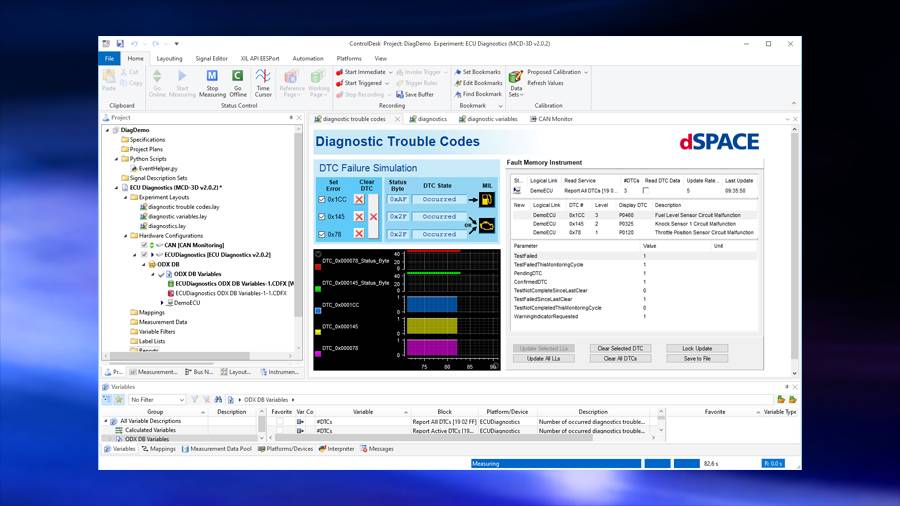

ECU 诊断模块

ControlDesk ECU诊断模块将ControlDesk扩展为一个全面、集成的测量、校准和诊断(MCD)工具。可轻松执行典型诊断任务,例如处理ECU的故障内存、运行诊断服和闪存等。此外,可以与其他平台一起实现测量和校准设备的变量导向工作。

- 适用于不同开发阶段,例如通过HIL进行虚拟仿真、在快速原型开发背景下,或与真实ECU直接通信。

- 采用与ControlDesk中支持的其他数据源(例如HIL中环境模型的变量)相同的方式同时使用校准、测量和记录诊断数据。

- 完全可用于通过MCD-3D的标准API和ControlDesk应用编程接口(API)进行自动化测试。

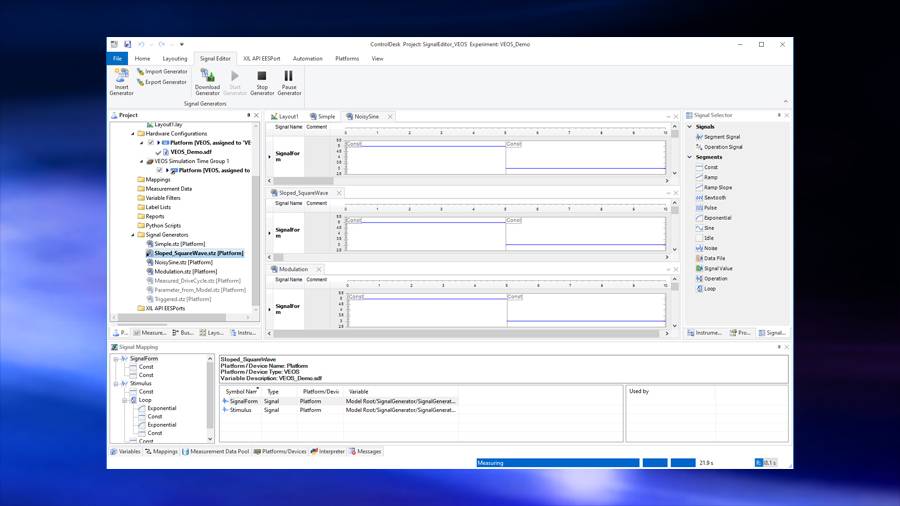

信号编辑器模块

这个可选的ControlDesk软件模块用于图形化定义和执行信号发生器,以刺激实时/离线仿真应用的模型变量。

- 进行图形化激励定义

- 在dSPACE实时硬件上和dSPACE VEOS中仿真的Simulink模型上生成时间同步激励

- 回放测得的数据

- 可以独立执行多种激励模式

- 支持XIL API激励格式(STZ文件,即压缩的STI文件)

请注意:此模块不支持为DS1104生成信号。

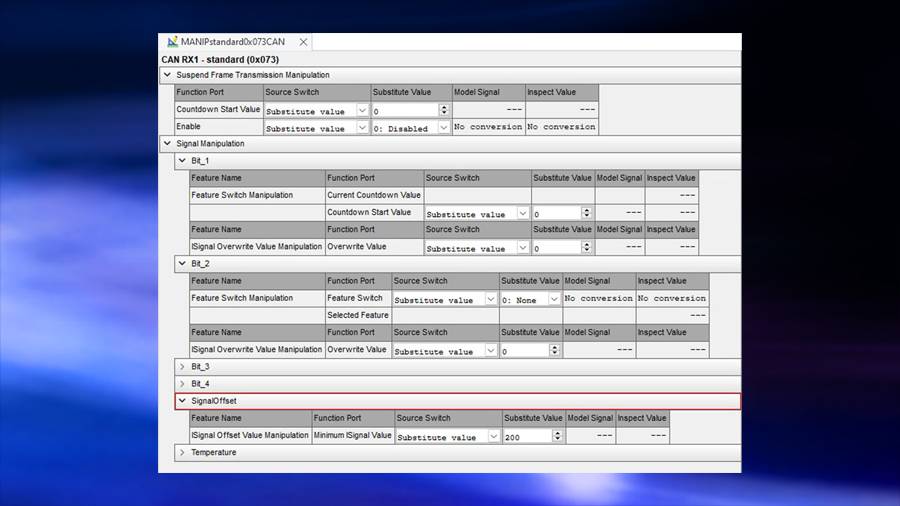

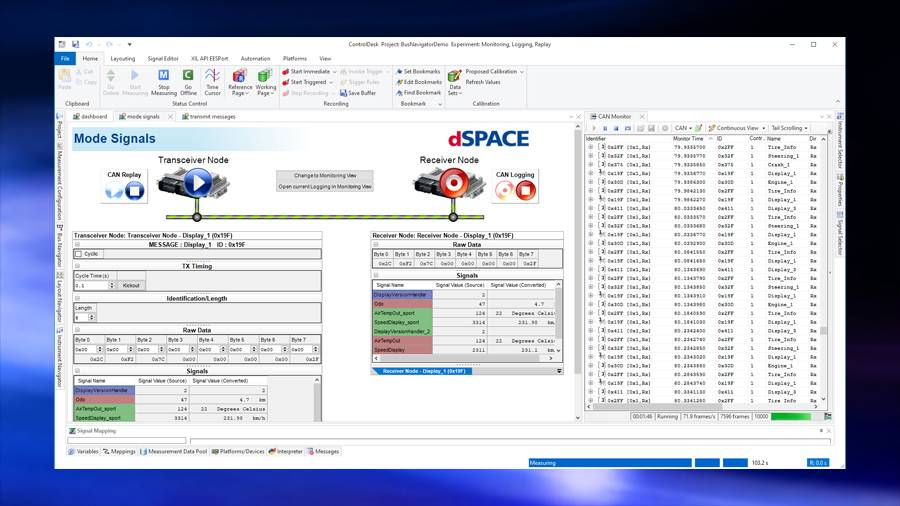

总线导航器模块

这个可选的ControlDesk软件模块可用于处理各种总线消息(例如CAN、LIN和FlexRay消息)、帧和PDU,以及以太网数据包。

- 支持CAN、CAN FD、LIN、Flexray和以太网总线

- CAN、CAN FD、LIN、Flexray和以太网总线对象的专用仪表

- 回放录制的CAN和CAN FD消息,回放以太网通信

- dSPACE硬件、dSPACE VEOS和PC总线接口的CAN、CAN FD和LIN监测和记录

- 以太网总线监测(dSPACE SCALEXIO、Vector接口、PC以太网接口(包括回送))

- CAN和LIN总线统计数据

- 也可用作Bus Navigator(独立版本),主要侧重于总线连接并且更经济高效

请注意:Bus Navigator(独立式)不支持FlexRay。

更多深度信息

通过ControlDesk进行以太网总线监测和记录

ControlDesk现在提供 Ethernet Bus Monitoring 装置,可用于监测和记录以太网通信。它支持全面的网络数据包分析,并支持以下协议:Ethernet II、IPv4、IPv6、UDP、TCP/IP和SOME/IP-SD为了提高以太网监控的可读性,可以显示ECU的名称而不是它们的MAC/IP地址。此外,还引入了解码视图,这样就可以查看所选以太网帧的协议数据。

时间光标在特定的时间点将被监测的以太网流量数据与测量数据以及其他协议进行比较,如CAN、LIN和FlexRay。此外,其中的以太网筛选器允许您指定捕获的以太网数据包。以太网监测数据可以保存成 PCAP NG文件

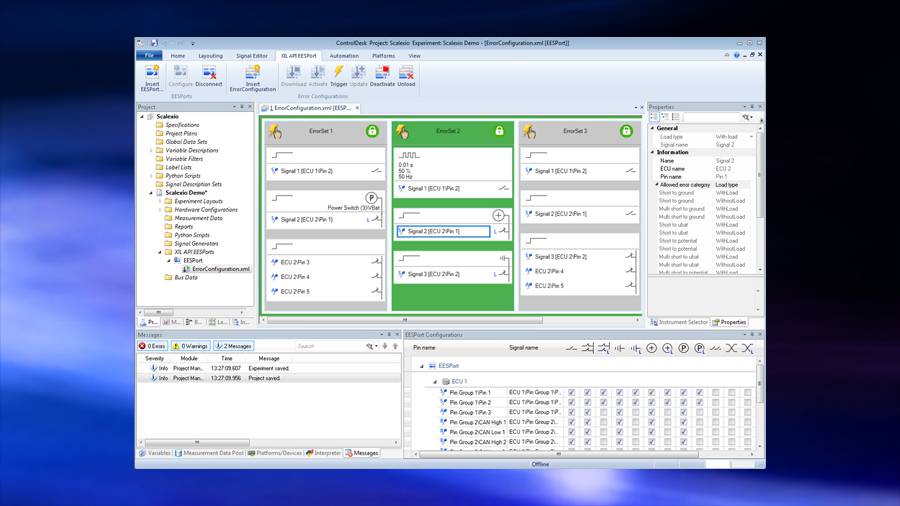

XIL API EESPort GUI:直观的故障插入和仿真

XIL API EESPort(Electrical Error Simulation Port)图形用户界面不仅可以(通过XIL API EESPort服务器)方便地控制电气错误仿真硬件,还可以直接从ControlDesk as an XIL API EESPort客户端对错误集和错误配置(相当于错误图像)进行交互式图形配置。此解决方案符合ASAM XIL API标准,可为所有dSPACE SCALEXIO和PHS故障插入单元(FIU)提供统一支持。

带有XIL API EESPort GUI

- 交互式处理电气错误仿真的图形用户界面,符合ASAM AE XIL API标准(EESPort)

- 创建错误配置、错误集和错误

- 执行电气错误仿真(例如,下载和激活错误配置,以及触发错误集)

- 涵盖 dSPACE SCALEXIO 及 dSPACE 中型和大型仿真器

- 方便 XIL API 错误配置和错误集统一用于各种故障插入单元

- 支持通过 FIU 追踪所激活的 XIL API EESPort 错误集

- 增强控制条,更方便过滤错误类型

- 扩展的自动化支持

- 要求故障仿真包

- 故障配置命令也可在全屏模式下使用

- EESPort的创建基于非dSPACE EESPort实现

- 通过Ethernet‑to‑RS232 转换器的支持控制dSPACE故障仿真硬件