Environment Sensor Interface Unit

Alimentation des calculateurs de caméra, de radar et de lidar en données numériques

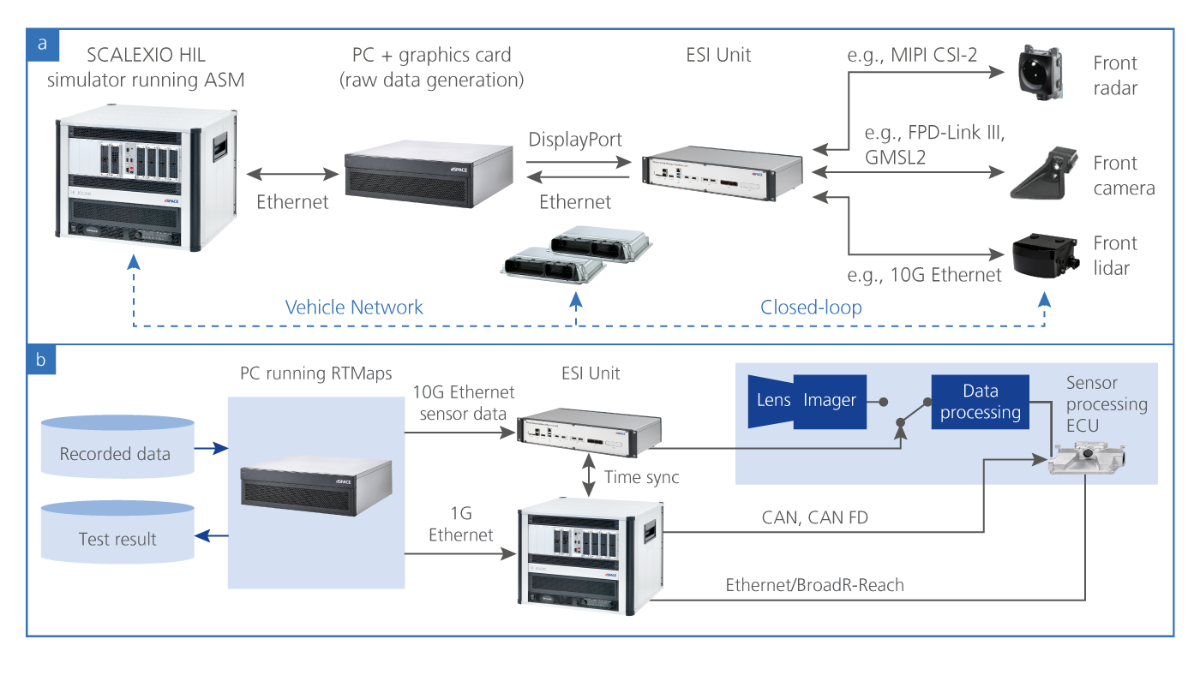

Les systèmes destinés à la conduite autonome utilisent divers capteurs d’environnement. Afin de simuler les capteurs dans une installation HIL réalisée pour la fusion de capteurs et les tests de fonction, il est essentiel de synchroniser précisément la stimulation de chaque capteur. L’unité Environnement Sensor Interface Unit de dSPACE supporte l’alimentation corrélée dans le temps des données brutes des capteurs vers un ou plusieurs calculateurs de capteurs.

-

Unités ESI préconfigurées

L'Environment Sensor Interface Unit (Unité ESI) de dSPACE permet d'alimenter les calculateurs ADAS/AD en données de capteur brutes réelles et simulées de manière corrélée dans le temps. Ceci est notamment extrêmement utile pour les tests HIL des fonctions de conduite autonome. Pour faciliter au maximum ces tests, dSPACE propose désormais également des unités ESI préconfigurées pour des scénarios applicatifs spécifiques et largement utilisés :

- Kit ESI YUV : Environment Sensor Interface Unit préconfiguré pour simulation de caméra YUV (GMSL2 ou FPD-Link III)

- Kit ESI DRIVE : Environment Sensor Interface Unit préconfiguré pour NVIDIA® DRIVE AGX

- FPGA hautes performances pour alimenter les calculateurs des capteurs en données brutes de manière synchronisée

- Adaptation flexible des interfaces de données brutes courte et longue portée, y compris les modèles de capteurs basés sur FPGA

- Support pour ADI/Maxim GMSL1/2/3, TI FPD-Link III/IV, Sony GVIF2/3, et MIPI CSI-2 D-PHY

- Simulation allant jusqu’à 12 capteurs avec une bande passante agrégée de 50 Gbit/s

Domaines d’application

Pour le développement et la validation des capteurs d'environnement, par exemple radar, caméra et lidar, et plus généralement la validation des fonctions ADAS/AD, il est essentiel de supporter une gamme d'interfaces de calculateur pour l'insertion de données. Outre les tests basés sur des méthodes « over-the-air » et des listes d'objets, l'insertion de données brutes ou de listes de cibles revêt une importance capitale pour la validation des algorithmes de perception et de fusion basés sur des données brutes. L’Environment Sensor Interface (ESI) Unit supporte toutes les interfaces de capteur pertinentes et est importante pour les tests en boucle fermée et en boucle ouverte. La simulation de capteurs avancée en combinaison avec l'Unité ESI permet de fournir facilement des données de capteurs synthétiques dans des conditions réalistes et avec de faibles latences. C’est utile pour valider les fonctions de conduite autonome en simulation HIL (boucle fermée et ouverte). Si RTMaps est également utilisé, les données de capteurs enregistrées peuvent être rejouées facilement. Un avantage majeur de l'Unité ESI est qu'elle peut être utilisée pour traiter à la fois le rejeu de données et la simulation de capteurs simultanément ou séquentiellement et sur le même simulateur HIL.

Avantages majeurs

L'Environment Sensor Interface supporte l'injection de données brutes et de listes de cibles pour les tests HIL des calculateurs de caméra, de radar et de lidar ainsi que des calculateurs pour la conduite autonome. Grâce à son architecture flexible et évolutive, l'Unité ESI supporte les tâches telles que l'injection de données de nuages de points lidar via Ethernet 10 Gigabit, l'injection de données brutes radar via MIPI CSI-2 D-PHY et l'injection de données brutes caméra via ADI/Maxim GMSL1/2/3, TI FPD-Link III/IV, Sony GVIF2/3 ou MIPI A-PHY. Pour répondre aux exigences des calculateurs de nouvelle génération, l’Unité ESI peut être configurée pour simuler les derniers capteurs, y compris les modèles de capteurs basés sur FPGA. Une seule Unité ESI simule jusqu'à douze capteurs de manière synchrone et supporte plus de 50 Gbit/s de bande passante agrégée. Plusieurs Unités ESI combinées vous permettent de tester les fonctions de conduite autonome avec des dizaines de capteurs différents. Les exigences et fonctions particulières des clients peuvent être implémentées directement sur l'Unité ESI grâce au puissant FPGA Xilinx® UltraScale+™.

Environment Sensor Interface Unit préconfigurée

dSPACE propose des Unités ESI préconfigurées pour des scénarios d'application spécifiques largement utilisés. Tous les kits gèrent la simulation de 4 caméras en utilisant des données de capteurs synthétiques (avec AURELION) et des données de capteurs enregistrées (avec RTMaps) :

- Kit ESI YUV : Environment Sensor Interface Unit préconfigurée pour la simulation de caméra YUV (GMSL2 ou FPD-Link III)

- Kit ESI DRIVE : Environment Sensor Interface Unit préconfigurée pour NVIDIA® DRIVE AGX.

| Parameter | Specification |

|---|---|

|

FPGA |

|

|

Memory |

|

| Sensor interfaces |

|

| Input interfaces |

|

| Design |

|

| Cooling |

|

| Power supply |

|

| Weight |

|

| Size |

|

| Camera |

|

| Radar |

|

| Lidar |

|

1) Disponible sur demande.

-

- Afficher en ligne

- Téléchargement

- Enregistrement des données Notre mission est d’optimiser l’enregistrement de données, de permettre des réponses rapides aux nouvelles itérations d'apprentissage et de validation et de permettre des cycles de données très courts

- Système ADAS et conduite autonome Solution ouverte de simulation et de validation de bout en bout pour une conduite autonome sécurisée

- Système HIL en boucle ouverte pour les tests de calculateurs de traitement d’images Système HIL en boucle ouverte pour les tests de calculateurs de traitement d’images

- Tests HIL en boucle fermée de systèmes de caméras Système HIL en boucle fermée permettant de tester les systèmes basés sur caméra en insérant des données au niveau de la sortie du capteur d’image

- Tests HIL en boucle fermée de systèmes à capteurs multiples Tests HIL en boucle fermée de systèmes à capteurs multiples

Faire avancer l'innovation. Toujours à la pointe de l'évolution technologique.

S’abonner à nos newsletters, gérer ses abonnements ou se désabonner. La newsletter mensuelle contenant toutes les informations liées à l’aéronautique et défense.