ASM Combustion Engines

Real-Time-Capable Simulation Models for Combustion Engines

The ASM engine models are ideal for developing and testing engine and exhaust gas aftertreatment ECUs. They simulate a combustion engine, including all the necessary components, as a controlled system for the ECUs. There are models for diesel and gasoline engines with different injection systems and exhaust gas aftertreatment systems. The real-time simulations can be performed with mean-value models or with models of physical precision.

-

ModelDesk Processing

Support of ModelDesk processing as a successor of ASM Parameterization

-

Modeling the future

To meet new requirements for the exhaust behavior of combustion engines, the relevant development and test environments have to be continuously developed as well. For new engine generations, Weichai therefore uses dSPACE Automotive Simulation Models and dSPACE SYNECT.

-

A Moving Variety

For commercial vehicles, diversity is a standard. Scania has a nearly endless selection of vehicle types and modular vehicle configurations. And the generic electronic control unit (ECU) system has just as many variants. In a new test lab, Scania shows how this system can be validated with reliability. -

Top Performer

One thing is for certain: If you start a large high-performance gas engine with a suitable generator, you are the best-motorized employee on site – at an electric power of up to 4,500 kW. Such powerful machines are used primarily for the stationary generation of energy and heat. Caterpillar Energy Solutions developed an entirely new control to ensure that future energy plants remain effi cient, dynamic, and maintenance-friendly.

-

Virtual Winter Tests

No modern vehicle ever reaches the market without first undergoing exhaustive tests. And test vehicles alone are no longer enough to test the complex electronic control units. This job is performed by simulation models, which shift ECU development into the virtual reality of a virtual vehicle. Dr. Hagen Haupt, head of dSPACE's Modeling Group, explains how the dSPACE simulation models are meeting this challenge.

- Open MATLAB®/Simulink® model

- For ECU testing and function development

- Intuitive graphical parameterization in ModelDesk

Mean Value Models

Benefit

Mean value models have excellent real-time behavior. They are accurate enough to give plausible signals to conventional engine controls, which makes it possible to check the ECUs’ functions and diagnostic capabilities.

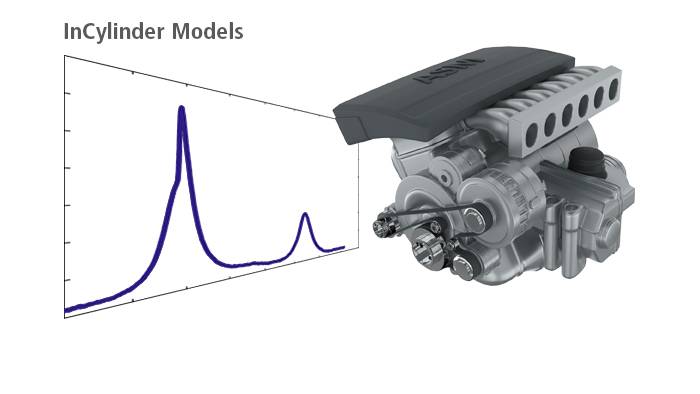

In-Cylinder Models

In-cylinder models simulate the state variables of the combustion engine consistently at each time instance and synchronously to the crank angle. On real-time computers, they help calculate the thermodynamic processes in the cylinder and the gas mass flow through the intake and exhaust valves synchronously to the crankshaft rotation.

Benefit

The quality that simulations reach with in-cylinder models is rather high. In-cylinder models provide crank-angle-synchronous representations of the effects of the combustion and gas exchange process for each cylinder. The models are also required for ECUs that evaluate the cylinder pressure and control each intake and exhaust valve individually in timing and lift.

| Feature | Gasoline Basic | Gasoline | Diesel | InCylinder Gasoline | InCylinder Diesel |

|---|---|---|---|---|---|

| No. of cylinders | Unlimited | 20 | 20 | 12 | 12 |

| EGR | – | Yes | Yes | Yes | Yes |

| Map-based turbocharger | Yes | Yes | Yes | Yes | Yes |

| Physical turbocharger | – | Yes | Yes | Yes | Yes |

| Common rail system | – | Yes | Yes | Yes | Yes |

| Pump nozzle | – | – | Yes | – | – |

| Fuel injection | Intake manifold | Direct, intake manifold | Direct | Direct, intake manifold | Direct |

| Wall film evaporation | Yes | Yes | – | – | – |

| Combustion modes | Homogeneous | Homogeneous, stratified | Diffusion | Homogeneous | Diffusion |

| Exhaust system | Basic variant | Basic variant | DPF, DOC 1) | Basic variant | DPF, DOC 1) |

| Soft ECU, engine | Yes | Yes 2) | Yes 2) | Yes 2) | Yes 2) |

| Combustion simulation | Mean value | Mean value | Mean value | Physical | Physical |

| Valve simulation | Mean value | Mean value | Mean value | Physical | Physical |

ASM Engine Models

Overview of mean value models and InCylinder models.

ASM Gasoline Engine is a mean value engine model with torque modulation and exhaust gas system.

ASM Diesel EngineASM Diesel Engine is a mean value engine model with torque modulation and exhaust gas system.

ASM Gasoline Engine InCylinderASM Gasoline Engine InCylinder is a real-time-capable gasoline engine model with in-cylinder pressure and temperature simulation.

ASM Diesel Engine InCylinderASM Diesel Engine InCylinder is a real-time-capable diesel engine model with in-cylinder pressure and temperature simulation.

-

- View online

- Download

Drive innovation forward. Always on the pulse of technology development.

Subscribe to our expert knowledge. Learn from our successful project examples. Keep up to date on simulation and validation. Subscribe to/manage dSPACE direct and aerospace & defense now.