ASM Diesel Exhaust System

Diesel exhaust aftertreatment

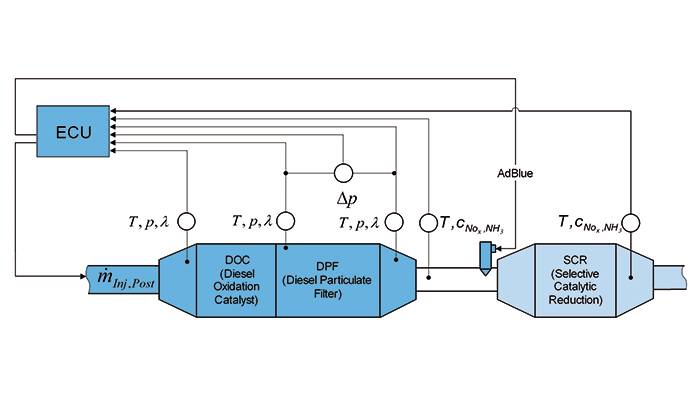

Real-time simulation of a complete diesel exhaust aftertreatment system.

- Diesel oxygen catalyst (DOC),

- Diesel particulate filter (DPF)

- Selective catalytic reduction (SCR)

- Physical and chemical process simulation

Application Areas

The ASM Diesel Exhaust System Model is an extension to ASM Diesel Engine and ASM Diesel Engine InCylinder and provides variable configurations of diesel exhaust aftertreatment systems, supporting a DOC, a DPF and an SCR system.

Key Benefits

The various exhaust model components can be combined to match the aftertreatment system being tested, which ensures that it complies with the desired fuel consumption and emission standards.

Simulation Model Characteristics

The ASM Diesel Exhaust System Model mainly consists of a DOC, a DPF, and an SCR system. It covers typical sensor variables for ECUs in DOC and DPF applications, such as temperatures, pressures and lambda values. These applications investigate effects of soot trapped by filtering material and of DPF regeneration. The oxidation of post-injections and of fuel introduced by catalytic burners is also included in the model. With its solution for simulating common AdBlue and diesel exhaust fluid (DEF) dosing systems with and without air supply and its modeling concept for evaluating the urea decomposition and chemical process of the catalytic reduction, the ASM Diesel Exhaust System Model can be used as a basis for modeling today’s aftertreatment systems.

Features DOC, DPF Models

- Pressure drop over DOC/DPF

- Temperature before and after DOC/DPF

- Lambda before and after DOC/DPF

- Particulate mass in DPF

- DPF regeneration by post-injection or additional injection

Features SCR Model

- Zero-dimensional approach

- Series connection of identical cells

- Number of cells represents the sectional discretization

- Outputs of one cell are inputs of the following cell

- AdBlue dosing system configurations with and without air supply are provided as demo models

- Urea decomposition upstream of the SCR catalyst

-

- View online

- Download

- Automotive Simulation Models Tool suite for simulating the engine, vehicle dynamics, electrical system, and traffic environment

- ASM Combustion Engine Models Real-time models for diesel and gasoline engine simulation

Drive innovation forward. Always on the pulse of technology development.

Subscribe to our expert knowledge. Learn from our successful project examples. Keep up to date on simulation and validation. Subscribe to/manage dSPACE direct and aerospace & defense now.