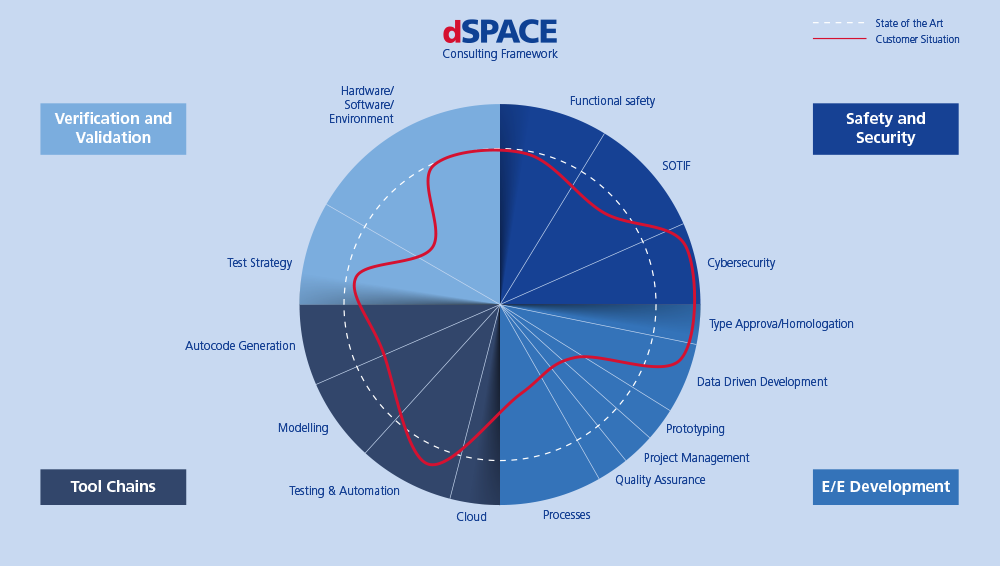

dSPACE咨询服务部的服务包括:

- 优化先进的测试系统,包括软件级,乃至车辆级。

- 通过详细分析测试前置和测试自动化等战略措施,显著节约成本。

- 利用优化工具链,达到高质量标准。

- 有庞大的合作伙伴网络,可以完成大型测试自动化项目,其中包括广泛的测试用例开发。

安全:ISO 26262和SOTIF

- 在所有开发阶段实施和优化符合ISO 26262和SOTIF标准的流程。

- 定义和鉴定HIL及机电测试台架的测试环境。

- 分类和鉴定系统及软件工具。

- 设计符合ISO 26262标准,基于模型的开发(MBD)流程,且达到最高ISO级别。

- 为基于场景和需求的设计制定测试策略,并进行专业风险分析。

网络安全:

- 对系统漏洞和风险持续进行安全管理,确保符合ISO/SAE 21434和UNECE WP.29的要求。

- 虚拟和真实ECU的SIL/HIL测试策略及验证,ECU之间车载通信的验证。

- 验证与车辆环境和接口(如WIFI、LTE/5G和GPS)的通信。

- OTA更新策略,用以支持持续认证过程。

dSPACE咨询服务部在多个项目中成功担负起了相应的临时职责。这些职责包括:

- 安全管理、风险管理、质量保证和项目主管

- 系统架构工程设计与验证、软件开发与验证

- 与我们的合作伙伴(TÜV)一起开展认证过程

在实施方面,dSPACE咨询服务部将扎实的理论知识与多年的实践经验相结合:

- 从传统软件开发转变成敏捷开发(DevOps)。

- 持续的集成、开发和测试策略,自动满足监管过程要求。

- 实施符合ISO 26262标准的工具链,支持基于模型的开发,包括自动代码生成,达到最高安全等级。

- 测试策略定义、测试自动化以及端到端工具链的开发和管理,顺利集成MIL、SIL和HIL。