Der jüngste Elektrifizierungstrend in der Automobilindustrie hat den dringenden Bedarf geweckt, elektrifizierte Systeme in der Antriebsstrangentwicklung anzupassen. Dieser Anpassungsprozess ist komplexer geworden, so dass Toyota die innovativen dSPACE Automatisierungslösungen einsetzt, um mehr Effizienz zu erreichen.

Testumgebungen erfordern integrierte Automatisierungsplattformen

Es gibt zwei Hauptanforderungen für das Vorverlagern von Anpassungs- und Evaluierungsaufgaben sowie zur Verbesserung von Effizienz und Produktivität:

- Durchführung von standardisierten Automatisierungsmethoden an Prüfständen für verschiedene Antriebsstränge

- Einsatz von Prüfstandautomatisierungsplattformen, die flexibel in verschiedene Prüfstände integriert werden können

Herausforderung Testeffizienz

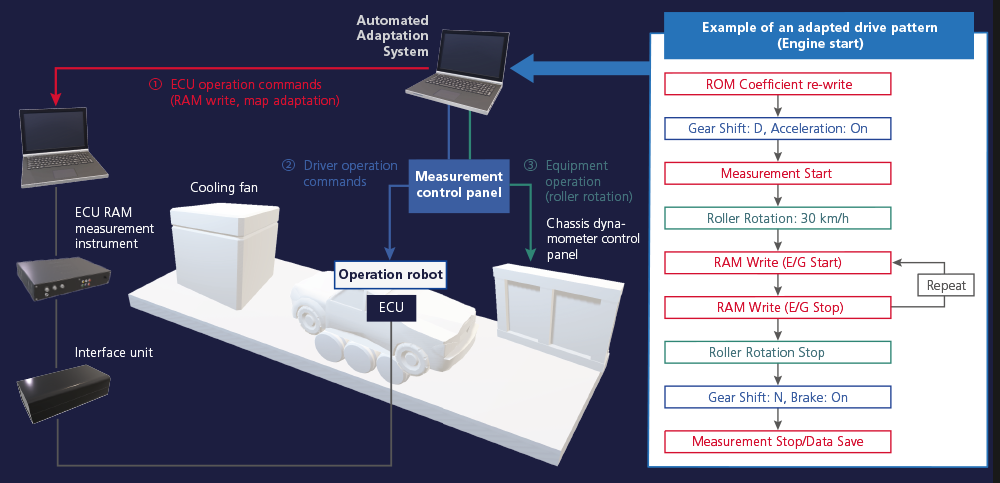

Um effizient mit Prüfständen arbeiten zu können, müssen diese fernsteuerbar, automatisierbar und die Testabläufe für Prüfstände unterschiedlicher Hersteller und für verschiedene Messgeräte einfach und flexibel anpassbar sein. Tomoki Taira, ein Prüfstandentwickler, erklärt: „Ich wollte das Testteam mit einem Werkzeug unterstützen, das viele manuelle Eingriffe abnimmt.“ Er fügt hinzu: „In den meisten Tests können die Fahrmodi in mehrere Klassen eingeteilt werden, so dass der Wechsel von der Basis einfach und schnell sein muss.“ Daher implementierte Tomoki Taira einen allgemeinen Betriebsablauf, indem er die Prüfstandprozesse analysierte, zerlegte und rekonstruierte und sie dann in die folgenden drei Kategorien gruppierte, um sie zu automatisieren:

- Steuergeräteprozesse (Schreiben und Messen von RAM-Variablen in der Steuergeräte-Software usw.)

- Fahrbetrieb (Beschleunigen, Bremsen, Schalten)

- Prüfstandbetrieb (Rollen-/Dynamometer-Drehzahl etc.)

Toyota suchte nach einer vielseitigen und leicht erweiterbaren Plattform, die diese drei Punkte erfüllt.

Evaluierung einer Testautomatisierungslösung

In der Regel etabliert jedes Unternehmen seine eigenen Lösungen zur Prüfstandautomatisierung. Die Nachteile dabei sind Entwürfe, die auf proprietären Standards basieren, hohe Preise und schlechte Anpassbarkeit. Aufgehoben werden diese Nachteile durch die Werkzeugkette der Automatisierungslösungen SYNECT und AutomationDesk von dSPACE. Die Werkzeugkette bietet Folgendes:

- Umgebungsintegration mit standardmäßigen ASAM-konformen Schnittstellen

- Hohe Vielseitigkeit in Bezug auf Ausgabedatenformate usw.

- Zusätzliche Automatisierungsfunktionen in einem angemessenen Preisbereich

- Hohe Kompatibilität mit den vielseitigen dSPACE Basisplattformen

- Gemeinsam nutzbare und wiederverwendbare Client-Server-Testszenarien

Shun Sekimoto, verantwortlich für Prüfstände bei Toyota, kommentiert: „Wenn es uns gelingt, AutomationDesk und SYNECT als Automatisierungslösung für unsere Prüfstände einzusetzen, werden wir die gewünschte Flexibilität beim Testen haben, und das zu einem Bruchteil der Kosten anderer Lösungen.“

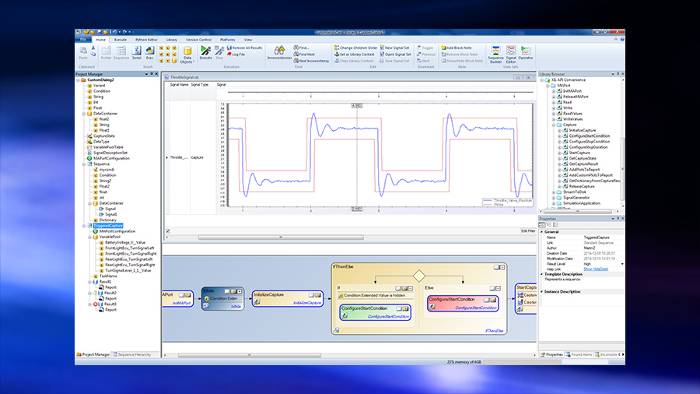

Implementieren der ausgewählten Testautomatisierungslösung

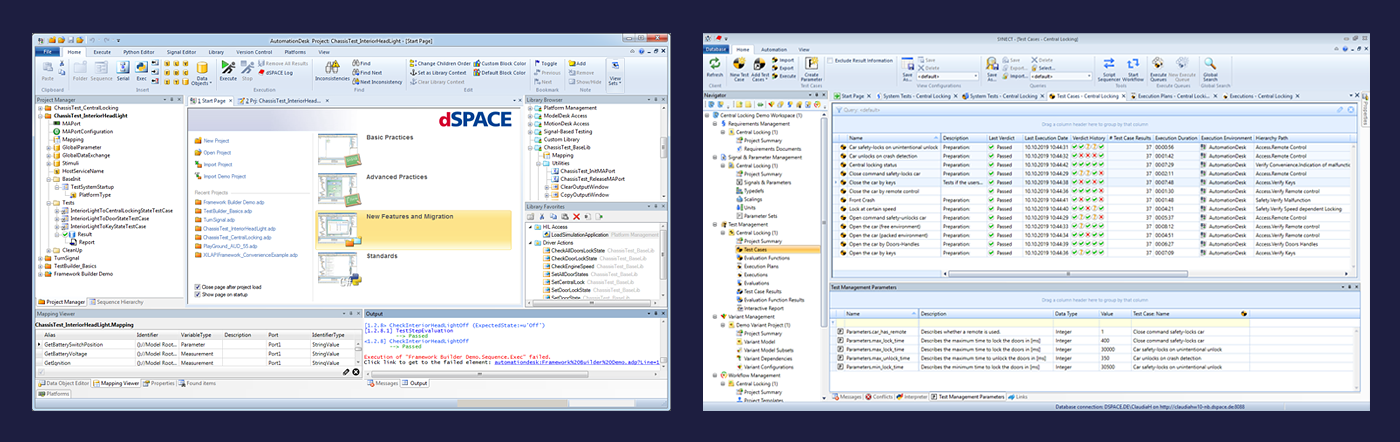

Die Prüfstandautomatisierung mit AutomationDesk wurde erfolgreich in einem Testaufbau demonstriert.

Die Grundideen:

- ASAM-Standards, die AutomationDesk bietet, um Standardschnittstellen mit Plattformen von Drittanbietern in Bibliotheken umzuwandeln und über ASAM-Standards wie XCP, ASAP3, XIL MAPort und ODS zu betreiben.

- Trennen von Testszenarien und Parametern, um wiederverwendbare und vielseitige Testvorlagen zu erstellen.

- Lernen aus Anwendungsfällen, wie Prozesse in die auf Steuergeräten, auf Treibern und auf dem Prüfstand unterteilt werden, und daraus notwendige Standard-Testszenarien erstellen..

Nach erfolgreicher Evaluierung wird diese Automatisierungslösung nun auf einer Reihe von Toyota-Prüfständen, wie Antriebsstrangprüfständen und Rollenprüfständen, eingesetzt. „Der Einsatz von AutomationDesk auf mehreren Prüfständen bietet uns eine leistungsfähige und besonders kostengünstige Prüfstandautomatisierung“, so Taira abschließend.

Effizientes Testmanagement

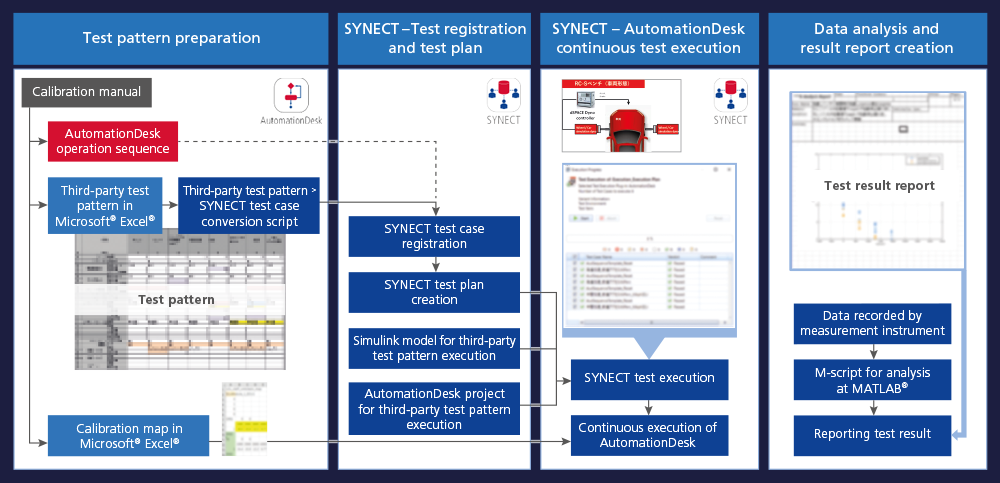

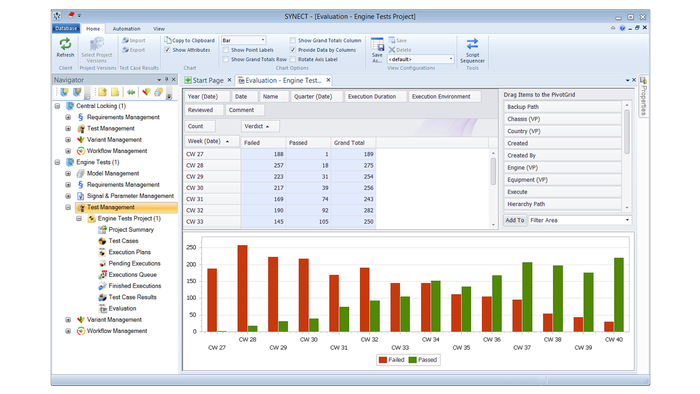

Da das Ziel nicht nur die Automatisierung von Abläufen auf Prüfständen war, sondern der Aufbau einer integrierten Entwicklungsplattform, setzte Taira dSPACE SYNECT ein, um die Entwicklungsprozesse auf Prüfständen zu überprüfen und zu optimieren.

- Herr Taira erstellte einen Mechanismus zur Planung und Verwaltung der Testausführung mit SYNECT Test Management.

- Er erweiterte SYNECT und AutomationDesk mit Hilfe von Python-Skripten zu einer Schnittstelle, die den gesamten Prozess von der Testregistrierung über die Testplanung bis hin zur Testdurchführung auf Endanwenderebene ausführen kann.

- Zur parallelen Testvorbereitung und -durchführung und um eine kontinuierliche Testdurchführung zu erreichen, nutzte er SYNECT, um die Arbeit in Offline-Umgebungen (Testregistrierung/Planung) von der Online-Arbeit (Testdurchführung) zu trennen.

- Er ermöglichte die gemeinsame Nutzung und Wiederverwendung von Test-Assets (aus Testszenarien und Testplänen) mit einer SYNECT Client-Server-Konfiguration.

„Da die Antriebssequenzen aller Prüfstände ähnlich sind, konnten sie leicht zwischen den Prüfständen ausgetauscht werden“, sagt Shun Sekimoto. Weiter führt er aus: „Durch die Trennung der Prozesse der am Testen beteiligten Stakeholder und die parallele Ausführung mit dem SYNECT Test Management zur zentralen Steuerung der automatischen Testausführung in SYNECT war es möglich, Tests effizienter durchzuführen.“

Ergebnisse und Ausblick

Mit der leistungsstarken Automatisierungslösung auf Basis von AutomationDesk und SYNECT ist es einfach, Tests zu definieren und den Testfortschritt und -status (bestanden / nicht bestanden) während der kontinuierlichen Testausführung zu verfolgen. Die komfortablen grafischen Benutzeroberflächen machen es besonders einfach, Testabläufe neu anzuordnen, Wiederholungen und Kombinationen von Testabläufen zu erstellen und übersichtlich zu visualisieren. Einfache Änderungen von Testabläufen und Testmustern können zentral vorgenommen werden. Diese schnellen Teständerungen erleichtern den Testalltag und erhöhen die Testtiefe. Außerdem verbessern sie die Zusammenarbeit mit den am Testprozess beteiligten Akteuren erheblich. Mit den dSPACE Werkzeugen gelang es Toyota, Anpassungs- und Evaluierungsaufgaben voranzutreiben und Prozesse zu optimieren. Vor dem Hintergrund dieser Erfolge adaptiert und erweitert Toyota derzeit die Prozesse auf weitere Prüfstände.

Mit freundlicher Genehmigung von Toyota