Renault has set up a new test factory in Romania to achieve a high throughput of test executions when developing and validating powertrain control units. The installed SCALEXIO and PHS systems can be used flexibly for ECU testing – the workflows are the same for both systems. This is achieved with the help of a newly introduced tool chain that is based on a specially developed management system and dSPACE tools.

Diversity in the vehicle range increases the number of powertrain variants: The range covers different motor and gear models in various combinations with or without the support of electric motors. In addition to hybrid drives, increasingly more battery electric systems are being developed. Automobile manufacturers, such as Renault, are therefore facing ever more challenges in the area of powertrain ECU development and validation, for example, with regard to efficiently managing development and test data. The aim is to simulate ECU variants by simply making changes in the software.

Depending on the vehicle type, engine size, transmission type, and engine concept, the ECU software must be adapted to the respective application. Developers are therefore confronted with enormous workloads, because all possible combinations must be tested and validated. At the same time, the validation process becomes more and more demanding, since an increasing interconnectivity of control units in vehicles and new vehicle functions such as advanced driver assistance systems (ADAS) result in ever more complex tests.

Developing Efficiently ...

Renault decided some time ago to optimize its powertrain development and testing processes to meet the future demands and to sustain the delivery of high-quality products with a short time to market. This meant Renault had to install a sufficient number of suitable test systems for control unit validation if they wanted to keep the highly complex tests simple and efficient.

... Using Automated HIL Tests

The large number of variants requires test systems that allow for a high throughput of test executions. It quickly became clear that Renault could only achieve this in the long term by redesigning its hardware-in-the-loop (HIL) tests and reaching a high degree of automation. Merely a few test systems would by no means suffice to do this, so the company decided to set up a new test factory in Romania. The idea: The test systems can be flexibly combined from a pool of HIL simulators to execute a wide variety of test tasks. Depending on the test task, the developer simply books the required test resources in the factory. This also resulted in new requirements for the simulators.

Variety Requires Processes and Structures

Each ECU variant requires a specific test environment, which essentially consists of the HIL simulator, the parameterized plant model, software tools, and other supporting tools. The environments required at Renault to validate the powertrain are now largely set up at the test factory in Romania where they are also used for ECU testing. One of the most diffi-cult tasks for the developers is to prepare the various HIL simulators on time for the respective test task because each variant requires a new configuration. In addition, each validation team member can book the test systems for their own testing purposes. Smooth procedures therefore require clear processes and structures that accurately define the way the teams work with the systems and the chronological sequence in which they perform the tests. Moreover, the large number of test environments can hardly be managed manually. So, to support their teams during test environment creation, Renault required a higher-level system that manages all necessary work steps and resources and enables build process automation.

The HELIUM Management System

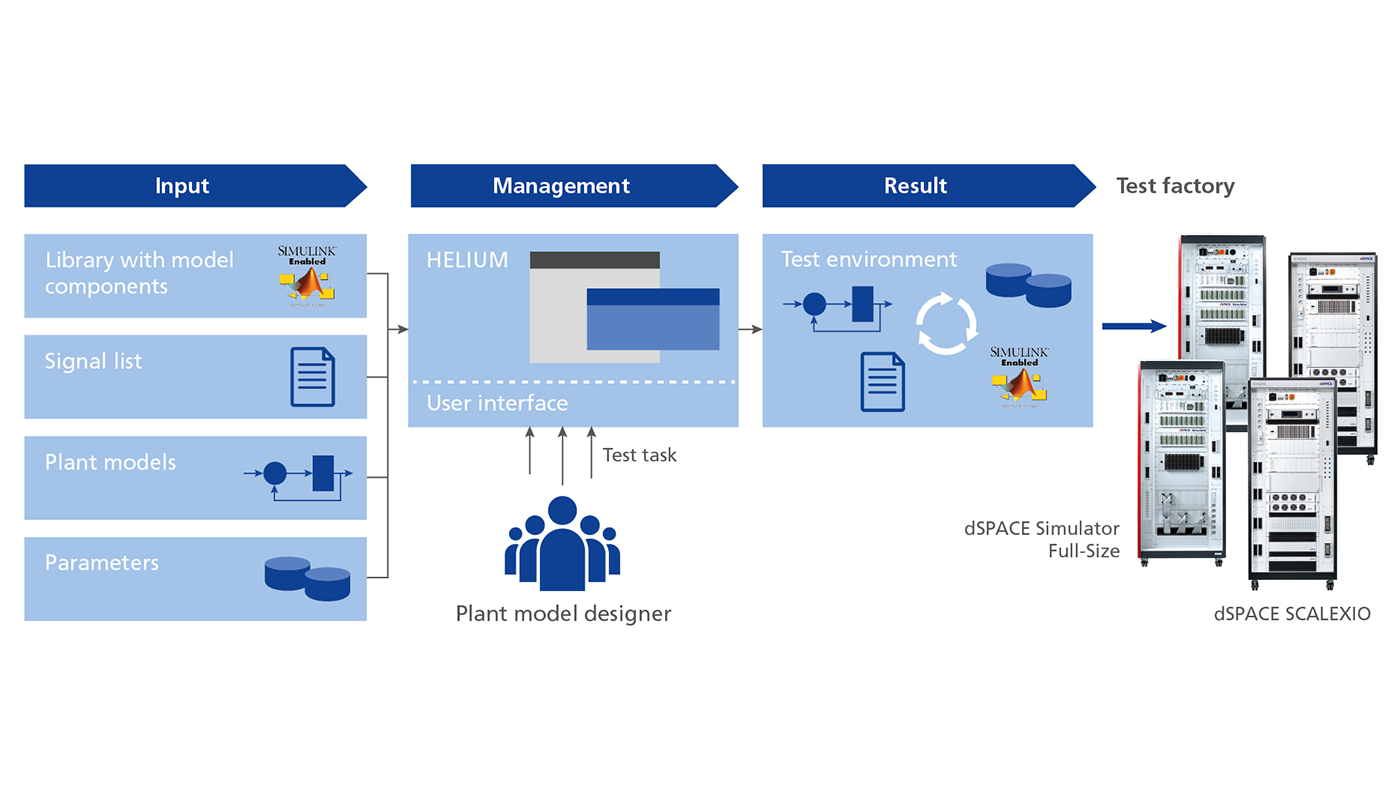

HELIUM is the name of the new tool that Renault designed specifically for powertrain development. It enables the automated creation of test environments for HIL-based tests. The developer can use the tool to automatically set up the environment and move it to a database or a repository. To do so, the software has an intuitive user interface which allows for starting the automatic build process at the click of a button. When the tool is connected to the simulator, the validation engineer can load the environment using a dedicated user interface in ControlDesk. Thanks to the simple and convenient workflows, testing time and potential errors are considerably reduced.

Test Factory Combining SCALEXIO and PHS Systems

The Romanian test factory currently consists of 34 dSPACE HIL simulators: 13 SCALEXIO systems and 21 PHS-based simulators that are used for testing new powertrain control units. As initially planned, the various systems can now be used flexibly for a wide range of ECU tests. This is possible mainly because of the standardized XIL API-compliant interfaces of the dSPACE tools, which enable interaction between different test hardware and software. The user interface is the same for SCALEXIO and PHS systems: The full parameterization is carried out in HELIUM. The workflow and the component models for automatically creating plant models are also the same. This allows for perfor-ming the same automated tests on all test systems.

High Throughput with Reliable Test System

With the help of the new tool and a few process optimizations, Renault can successfully manage the diverse variants in the powertrain area and meet the high demands placed on the validation process. Today, the team in Romania creates more than one hundred different test environments per year. The dSPACE systems played an important role in achieving this goal. Their versatility and easy integration into the Renault tool chain allow for flexibly adapting to project-specific requirements. At the same time, the dSPACE tools are highly standardized, which means that not all ECU variants require an individual test system. Overall, dSPACE test systems proved to be safe and reliable throughout the entire optimization process, creating the basis for today’s high ECU test throughput. Experienced dSPACE engineers have supported Renault directly on site in optimizing and executing the test processes.

Conclusion and Outlook

By using the new tool chain, the development team is able to maintain the efficiency of the development process and the quality of the HIL test environments even with a change in staff. Renault is already planning to further optimize the automation and the validation process, including the step-by-step introduction of 24/7 operation. New functionalities of dSPACE tools will also continuously be introduced in the tool chain. The aim is to soon also use the new process and tool chain in the company’s business alliance with Nissan.