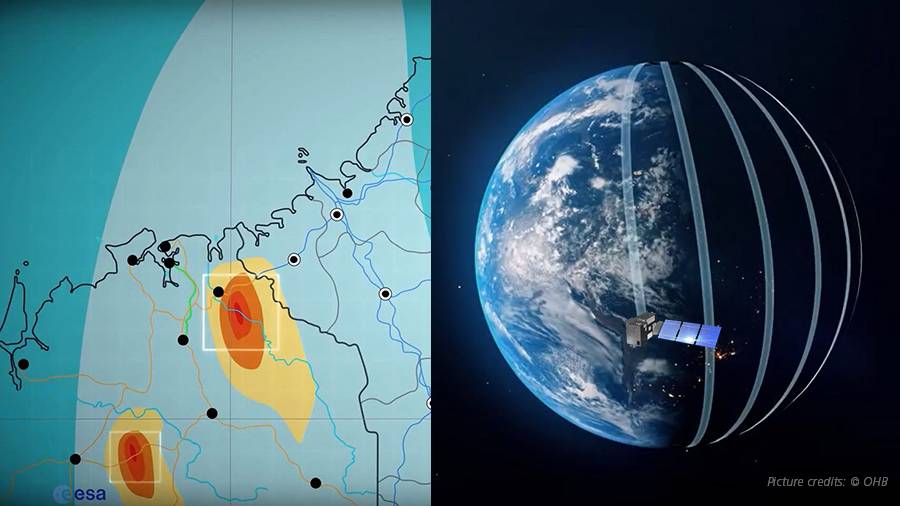

The European Space Agency (ESA) plans to launch the first of two satellites to measure global carbon dioxide (CO2) emissions from space with unprecedented accuracy in early 2026. Space technology company OHB is testing the satellite functions using simulators built on the basis of dSPACE SCALEXIO systems and software from Astos Solutions, among others.

To combat climate change, the world needs more accurate data on global CO2 emissions. The EU, with the support of ESA, would like to collect this data as part of the CO2M (Copernicus Anthropogenic Carbon Dioxide Monitoring) mission. The special thing about it: For the first time, it will be possible to distinguish man-made from natural CO2 emissions. This makes the CO2M mission an important building block for achieving the goal of the 2015 UN Climate Change Conference in Paris and limiting global warming to well below two degrees above pre-industrial levels.

Determination of Man-Made CO2

CO2 absorbs the infrared portion of light particularly strongly. Therefore, the satellites measure the intensity of the infrared light coming from the earth's surface and derive the CO2 concentration in the atmosphere from it. Furthermore, to distinguish man-made from natural CO2, the satellites also measure the concentration of nitrogen dioxide (NO2) using a similar method. This is because NO2 is produced as a by-product of CO2, primarily from the combustion of fossil fuels, but not as part of emissions from living organisms. NO2 can therefore be used as a marker to identify the man-made fraction of CO2 in the atmosphere, which, for example, is significantly higher in the atmosphere above an industrial region than above a sparsely populated tropical rainforest.

Crucial: Perfect Satellite Alignment

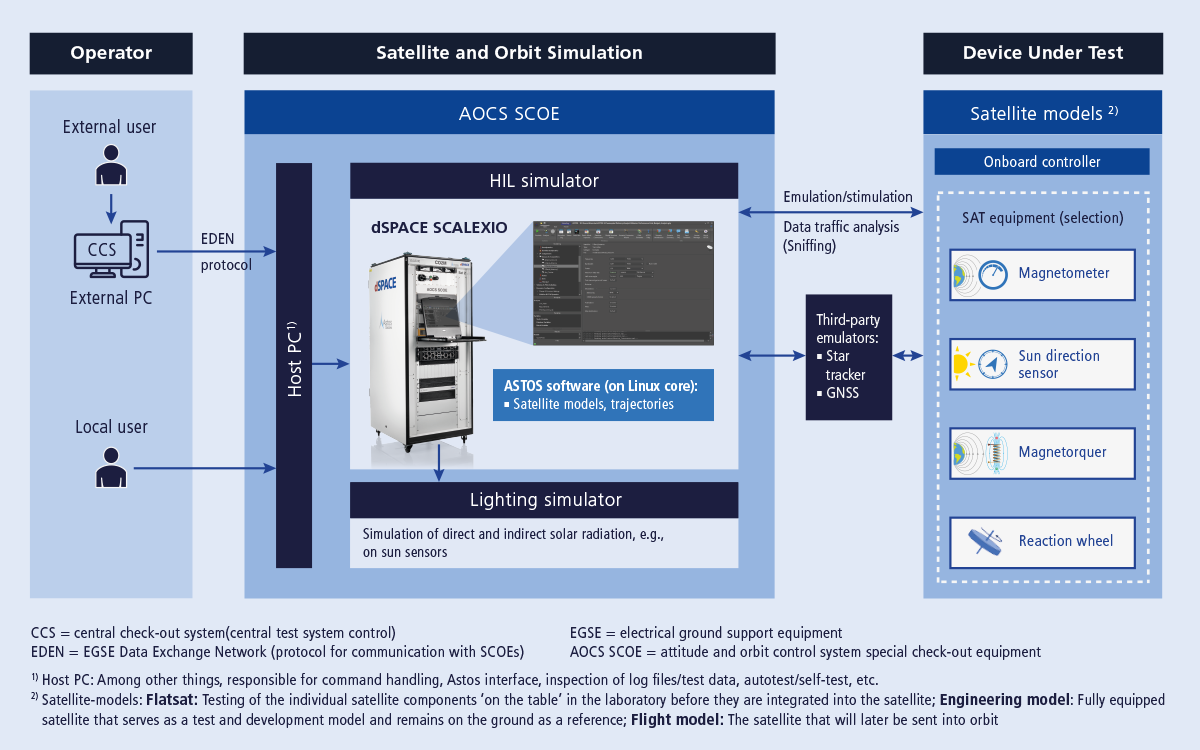

In order to perform accurate measurements, the satellites must precisely maintain their orientation and planned orbit. In spaceflight, this is ensured by an attitude and orbit control system (AOCS). A typical AOCS consists of a position control computer as well as sensors and actuators, for example:

- Magnetometer: Sensor for measuring the earth's magnetic field

- Sun direction sensor: Sensor for measuring the direction to the sun

- Magnetorquer: Actuator that applies torque to the satellite by means of an electromagnet interacting with the earth's magnetic field

- Reaction wheel: Actuator that applies torque to the satellite by means of a rotating flywheel mass

In addition, there is usually also a global navigation satellite system (GNSS) receiver. To test the AOCS in the laboratory, special check-out equipment (SCOE) is used. The AOCS SCOE for testing the CO2M satellites is based on a dSPACE SCALEXIO real-time system (Figure 2).

Simulating Conditions in Orbit

The AOCS SCOE can be used to simulate on-orbit conditions in the laboratory to test satellite functions. The typical influences to which the satellite is subject include the gravitational and magnetic field and friction with the residual atmosphere, which is extremely thin but still present in orbit at an altitude of 735 km. For the tests of the satellite systems, the highest requirements apply in terms of test coverage, because any error corrections are only possible by radio, for example in the form of software uploads, because the satellite is no longer accessible in orbit.

Figure 2: Architecture of the AOCS SCOE for testing the satellites. The ASTOS models are computed on the dSPACE SCALEXIO system on a Linux core (dSPACE Hypervisor Extension).

Structure of the AOCS SCOE

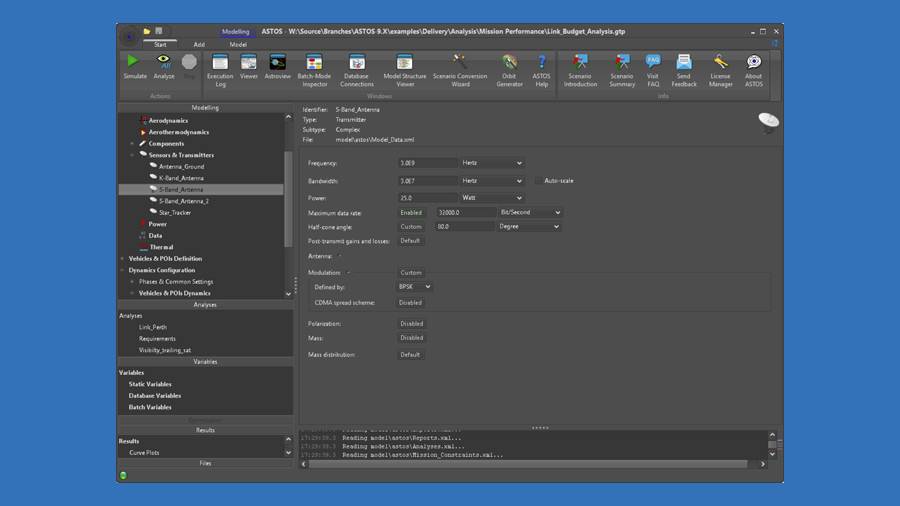

The SCALEXIO-based AOCS SCOE is being developed in collaboration between dSPACE and dSPACE partner Astos Solutions, which will subsequently deliver it to the space company OHB. The SCALEXIO system (Figure 3) supports a wide range of interfaces, including analog, digital, RS422, MIL-STD-1553, and Ethernet, for open-loop and closed-loop testing. On the SCALEXIO system, the satellite dynamics models are computed on a Linux core (dSPACE Hypervisor Extension, see info box). With the ASTOS-internal 3D engine developed by Astos Solutions, all test scenarios and their parameters can be visualized and monitored in real time for better clarity. The dSPACE SCALEXIO system also supports comprehensive automation for tests with automatic data recording around the clock.

Figure 3: Structure of the dSPACE SCALEXIO system used for the AOCS SCOE. A separate AOCS SCOE will be built for each of the satellites.

Special Requirements

Because the AOCS SCOE is connected directly to the hardware that will later fly into orbit, i.e., to the flight model, the dSPACE SCALEXIO system must meet very high requirements:

- Galvanic isolators to protect the satellite: both between the satellite and the AOCS SCOE and between the power supply of the AOCS SCOE and the mains

- Self-test procedure before connecting to satellites or device under test (DUT).

- Condition monitoring (temperature values, smoke development, general AOCS-SCOE status) retrievable locally on site and externally

- Time synchronization via PPS (pulse-per-second; Meinberg time signal)

- Halogen-free cable insulation

- Suitability of all components for use in the cleanroom

- Integrated host PC and slide-out console for local use

- Proof of electromagnetic compatibility

Profile: SCALEXIO Hypervisor Extension

The SCALEXIO Hypervisor Extension from dSPACE uses a kernel-based virtual machine (KVM). It runs the SCALEXIO real-time operating system and virtual machines with standard Linux distributions simultaneously. This enables the integration of Linux real-time and non-real-time applications, for example, Linux-based modeling and simulation tools, into the SCALEXIO real-time PC environment and supports low-latency, high-bandwidth data exchange between the two systems.

Profile: ASTOS Software

ASTOS software is suitable for spacecraft trajectory and design optimization, mission and system concept simulation, GNC/AOCS design and analysis, space debris/launch vehicle ascent safety and risk analysis, and failure budgeting. Powerful visualization capabilities allow calculation of resistivity and solar radiation disturbances for solar sail applications. A fluid workflow from model to processor to hardware-in-the-loop simulation is embedded in validation facilities. The EGSE product family is extended by a reconfigurable AOCS SCOE based on the dSPACE HIL product family and a camera and lidar simulator for real-time testing of image-processing-based navigation algorithms.

Satellite Tests at the Spaceport in Kourou

The launch of the first of the two CO2M satellites is scheduled for early 2026 from the spaceport in Kourou, French Guiana, on a Vega rocket. For this purpose, the dSPACE SCALEXIO system will also be on site in Kourou to test the satellites' functions before the launch. Both satellites are then expected to be operational in their orbit from 2026 at an altitude of 735 km. In subsequent years, the EU would like to increase the number of CO2M satellites to three. A dedicated AOCS SCOE based on dSPACE SCALEXIO systems would again be built for the additional satellite.

Company profile OHB

Headquartered in Bremen, OHB SE is a listed space and technology company comprising three business units: Space Systems, Aerospace, and Digital. In total, the Group has almost 3,000 employees at 15 locations throughout Europe. OHB SE's largest subsidiary, OHB System AG, which is headquartered in Bremen and has a further facility in Oberpfaffenhofen near Munich, has more than 40 years of experience in developing high-tech solutions for space flight and other fields of application. The portfolio of products and services ranges from the realization of satellite systems for earth observation, navigation, telecommunications, science, and reconnaissance to the development and implementation of missions for space exploration and the development of systems for astronautical space flight.

Company Profile Astos Solutions

Astos Solutions GmbH, which was founded in 2006 and is headquartered in Stuttgart, Germany, is a medium-sized company and one of the top suppliers of software and test systems used for space mission planning and spacecraft development. With its unique range of standardized and individual products and services, Astos Solutions GmbH offers solutions for a broad spectrum of applications. Typical areas of activity include analysis, simulation, trajectory optimization, animation, and visualization of mission analysis results in space applications.

About the authors:

Sven Weikert

Technical Director at Astos Solutions GmbH

Ann-Theres Schulz

Project Manager Standard Platform for Earth Observation Eos at OHB