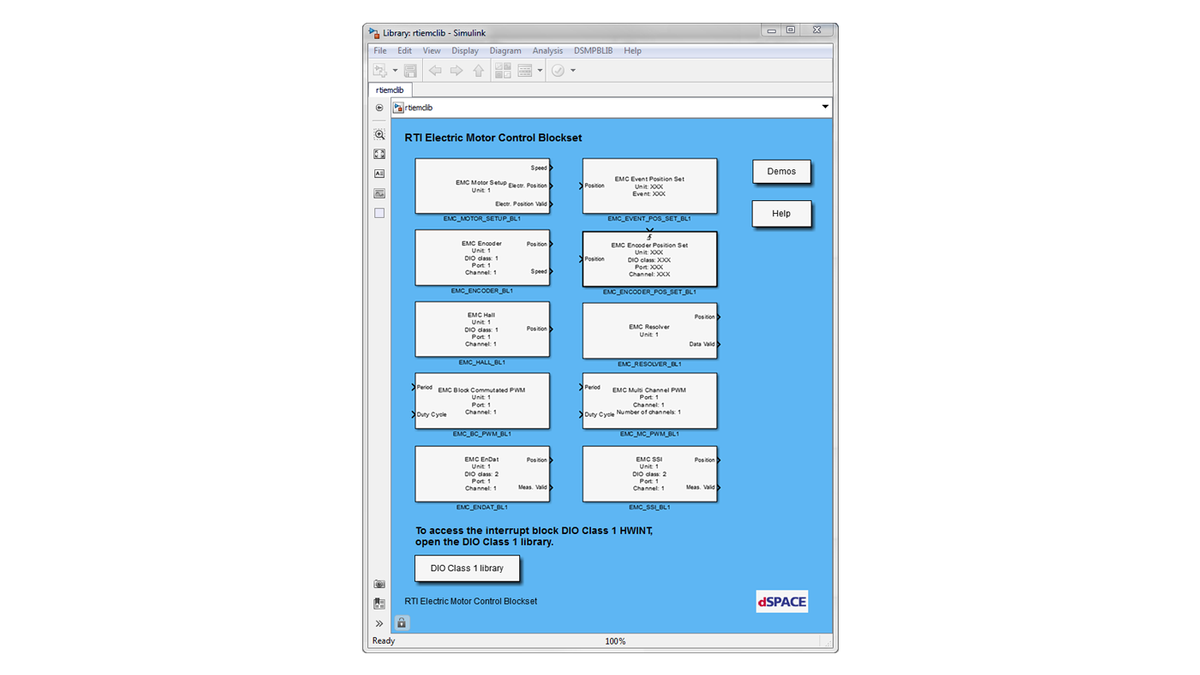

RTI Electric Motor Control Blockset

Configuring electric motor control I/O functions of MicroLabBox

The RTI Electric Motor Control Blockset, an extension of Real-Time Interface (RTI), provides access to the electric motor control I/O functionalities of MicroLabBox and lets you configure these easily and conveniently.

- Access to electric motor control specific I/O functionalities of MicroLabBox

- Easy configuration and implementation of Hall sensor inputs, incremental encoder, Resolver, EnDat, and SSI interfaces as well as PWM signal generation

- Automatic calculation and interpolation of the current motor speed, position, and angle, plus generation of asynchronous events

Application Areas

Electric motor controls play an important role in various application fields such as automotive industry, robotics, medical engineering, and many more, e.g., to comply with new, strict emission regulations or to build up more precise machines in industrial environments. Often, the control algorithm for an electric motor is a key point in fulfilling customers’ requirements. But the effort of developing, implementing, and validating the required control algorithms in traditional tool chains can be very high, and these tool chains often lack flexibility. The MicroLabBox in combination with the RTI Electric Motor Control Blockset is the ideal system to reduce this effort. Developing and testing new control algorithms takes place in a model-based software environment with a minimum amount of time. The RTI Electric Motor Control Blockset is a user-friendly software interface that provides a link between your real-time hardware platform MicroLabBox and the model-based development software MATLAB®/Simulink®/Stateflow® from Mathworks.

Key Benefits

The RTI Electric Motor Control Blockset provides access to the electric motor control specific I/O functionalities of MicroLabBox and allows you to configure them easily and conveniently. No additional modeling effort is needed to use sensor interfaces commonly applied in electric motor applications such as Hall sensors, incremental encoder, resolver, EnDat, or SSI. In addition, ready-to-use Simulink blocks for generating different synchronous PWM signals are available. The current speed, position and angle of the electric motor are automatically calculated. If sensor interfaces with low resolution such as Hall sensors are used, an automatic interpolation can be enabled to achieve a higher sensor resolution and to improve the quality of the position measurement. When first starting the motor to get the current motor position it is possible to use the Hall sensor interface immediately, and then switch to a sensor with the higher resolution such as the encoder interface after one revolution of the electric motor. With this process, a valid position and the best resolution is always available for the controller. Simulink-based control models can be easily connected with the required I/O interfaces and then be downloaded to the MicroLabBox at the push of a button. The controller can be tested in a real environment with different sensors and actuators, and new motor control strategies can be developed much faster than in traditional tool chains.

| Functionality | Description |

|---|---|

|

General |

|

- Ventes Notre équipe d’ingénieurs d’affaires vous assistera dans le choix de votre système dSPACE. Ils vous fourniront également les tarifs et toutes les informations souhaitées concernant d’autres produits dSPACE.

- Achat de logiciels dSPACE Informations sur le téléchargement, l’installation et le système de licence des logiciels dSPACE

Faire avancer l'innovation. Toujours à la pointe de l'évolution technologique.

S’abonner à nos newsletters, gérer ses abonnements ou se désabonner. La newsletter mensuelle contenant toutes les informations liées à l’aéronautique et défense.