Simulation Model for Ultrasonic Sensors

|

Published: September 15, 2020 |

Motivation

Haitz Aguirre Urizar, Senior Application Engineer Hardware-in-the-Loop Simulation and Thomas Zubert, Application Engineer Automated Driving & Software Solutions

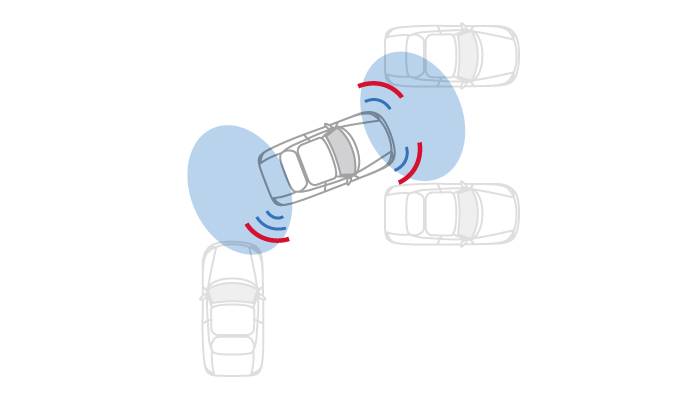

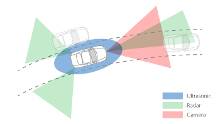

Ultrasonic sensors have been used in mainstream cars as a means of obstacle distance feedback for the driver since the early 2000s. Development in this area has continued and nowadays these sensors are also the key feedback components in automated parking maneuvers. Testing ultrasonic sensors is made difficult by their variations in number, mounting position, physical shape, paint color, and ultrasound characteristics. However, as the ultrasonic sensors play an important role in gathering information for the sensor fusion of near-field supervision and for achieving autonomous driving Levels 3, 4, and 5, not testing them thoroughly is not an option.

dSPACE developed a test system, the Ultrasonic Sensor Test System (Lab), to stimulate the ultrasonic sensors over the air. The system does not require any moving parts during run time. It is device-under-test- (DUT-)agnostic and can be coupled with the virtual dSPACE ASM Ultrasonic Sensor Model, which uses ray data to detect obstacles in a virtual environment.

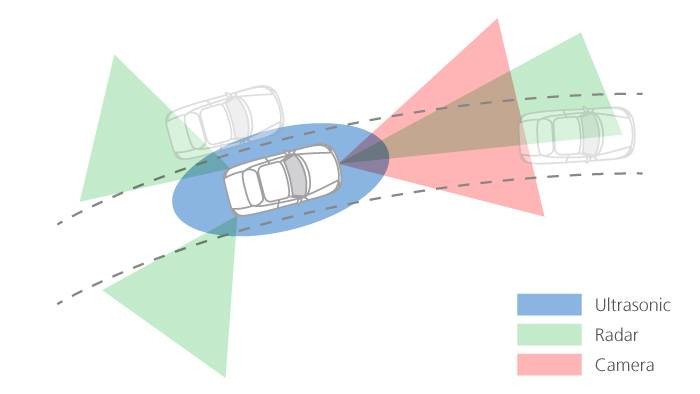

The system can also be used in conjunction with other dSPACE simulation options like camera and radar.

System Overview

The Ultrasonic Sensor Test System (Lab) typically consists of a real-time SCALEXIO Processing Unit running the ASM Vehicle Dynamics and Traffic modules, a high-performance FPGA board performing the low-level processing of the dSPACE transducer, and a communication network that reads the ECU output.

There is no tapping or manipulation between the DUT sensor and the ECU, which means the communication protocol does not have to be disclosed and the DUT system is considered a black box.

When the DUT sensor fires an ultrasound pulse packet to perform distance measurement, the packet is captured and processed by the dSPACE transceiver. After a time delay proportional to the distance, the dSPACE transceiver fires an ultrasound pulse back to the DUT sensor.

Ultrasonic Sensor Test System (Lab)

The test system is offered as stand-alone version or integrated in a SCALEXIO customized rack system. Existing dSPACE hardware-in-the-loop simulator chassis can be extended with the Mobile Ultrasonic Sensor Test System.

If you want to use the ECU outside of the rack housing, the ECU and its sensors are kept separate from the rack-internal signal wiring for convenience. In this case, the ECU side wiring is only fed through and not tapped. BNC connectors are provided at the front of the system for an accessible and convenient electrical checkout.

Even at a compact size of just 555 x 560 x 340 mm, the dSPACE system supports up to 12 sensors.

The dSPACE sensor and signal generators are connected to the real parking sensors over the air, attached with sensor clamps, and isolated from external interferences. The dSPACE real-time system is separate from the Ultrasonic Sensor Test System (Lab).

Software Overview

The software implementation running on the dSPACE real-time system consists of two parts: SCALEXIO Processing Unit and FPGA application.

- The SCALEXIO Processing Unit runs the ASM Ultrasonic Sensor Model, the ASM Traffic Model, and the interface blocks to and from the FPGA application.

- The FPGA application contains the low-level logic and is the interface to the I/O. Information regarding measurement schedule and modes are not required.

The interface between the processing unit and FPGA boards is used mainly to parameterize the FPGA application and monitor the FPGA low-level signals as well as the calculated wave characteristics, such as the frequency .

Features of the ASM Ultrasonic Sensor Model

The ASM Ultrasonic Sensor Model provides realistic echo calculation, which is used in the over-the-air simulation. The same model can be used for testing and developing algorithms in a software-in-the-loop simulation, giving our customers a seamless transition between different development stages. The model is developed for highly optimized calculations and runs on the processing unit of the SCALEXIO system without the use of additional GPUs.

The sensor model provides a number of features to get as close to real-world behavior as possible. The features include:

Realistic and Easy Object Parameterization

The ASM Ultrasonic Sensor Model uses a realistic and easy-to-use object parameterization model. Objects are defined by contour lines and their height, which leads to extruded contour lines. The objects have six degrees of freedom and can be used for any use case.

Direct and Indirect (Cross) Echoes

For direct echoes, the same sensor is used for sending and receiving. For indirect echoes (often called cross echoes), the sender and receiver of the echo differ. Indirect echoes provide additional information to the ECU and are therefore often required for valid detections. The ASM Ultrasonic Sensor Model calculates the direct and indirect echoes for each sensor.

Multiple Echoes per ECU Measurement

Modern ultrasonic sensors can detect and process multiple echoes from one or multiple objects. The ASM Ultrasonic Sensor Model provides multiple realistic echoes per object and across multiple objects for each send cycle.

Degrees of Freedom of the Ultrasonic Sensor FPGA Application

The dSPACE system uses four the degrees of freedom in the FPGA application to generate realistic echoes:

- Time of flight (ToF)

The ultrasound distance measurements are based on wave travel time. The time it takes the wave to travel forth and back is proportional to the distance. Environmental conditions, especially temperature, influence the wave speed in the air and can be considered for distance calculation in the dynamic model (simulation) or by means of a temperature chamber (physical). - Amplitude

Depending on the obstacle position, angle, and characteristics, part of the measurement energy bounces back and some is either absorbed or bounces in a different direction. The possibility to manipulate the amplitude of the generated echo provides realistic behavior. - Frequency

The FPGA application supports fixed and modulated frequencies in the typical automotive range. - Pulse number

The pulse number of the transmitted measurement wave may vary and this property is accordingly available in the FPGA application.

Frequency and pulse numbers might not be available for direct manipulation during run time.

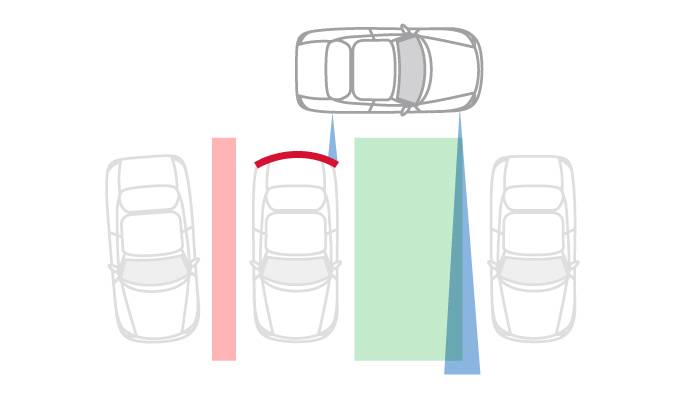

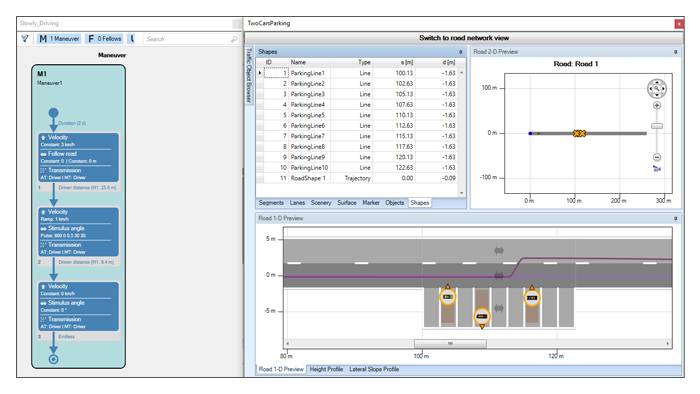

Application Example: Parking Space Measurement (PSM)

One of the many applications of the Ultrasonic Sensor Test System (Lab) and the ASM Ultrasonic Sensor Model system is the validation of parking space measurement (PSM) systems. These systems measure the width of a longitudinal or lateral parking space and initiate a parking maneuver. Such a scenario can be parameterized with dSPACE ModelDesk and visualized in real time with dSPACE MotionDesk and dSPACE ControlDesk. The Ultrasonic Sensor Test System (Lab) receives the calculated echoes from the model and stimulates the DUT ultrasonic sensors.

When a distance measurement from the device under test is triggered, the dSPACE sensor analyzes the waveform for characteristics such as frequency and amplitude. At the same time, a timer starts and when the time of flight proportional to the echo distance calculated by the ASM Ultrasonic Sensor Model is reached, the dSPACE signal generator triggers an echo signal with closely matching properties.

Advantages

The combination of the dSPACE Ultrasonic Sensor Test System (Lab) and the ASM Ultrasonic Sensor Model allows for the precise and reproducible simulation and test of an unlimited number of scenarios over the air. The integration of the ASM Ultrasonic Sensor Model in the dSPACE tool chain allows for easy and intuitive parameterization of scenarios and vivid visualization in MotionDesk. The Ultrasonic Sensor Test System (Lab) provides a solution for testing a real parking ECU and ultrasonic sensors without line tapping or moving parts during run time and is easy to integrate in existing systems. The test system is offered in a compact size, either as stand-alone version or as part of a full-size system. The system can be extended by other dSPACE sensor simulation options for fusion in ADAS/AD tasks, e.g., camera, lidar, and radar.

Drive innovation forward. Always on the pulse of technology development.

Subscribe to our expert knowledge. Learn from our successful project examples. Keep up to date on simulation and validation. Subscribe to/manage dSPACE direct and aerospace & defense now.