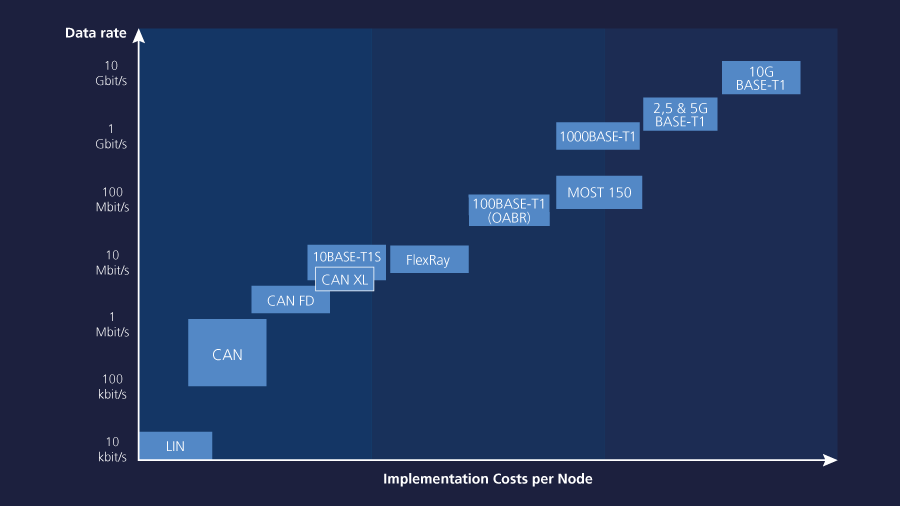

Bus systems form the information backbone of today’s vehicles and their ECU communication. Established communication technologies such as CAN, CAN FD, FlexRay and LIN are still largely used as they are proven and cost-efficient. Nevertheless, the trend of using Ethernet in the automotive sector continues.

The current automotive Ethernet semiconductors allow for transmission rates from 10 Mbit/s up to 10 Gbit/s using a single twisted cable pair. Due to the large number of protocols in use, such as SOME/IP, gPTP, TLS, IPsec, or MACsec, among others, managing communication is rapidly becoming more complex.

dSPACE provides suitable solutions for different applications to get on top of things. Our software and hardware portfolio cover topics such as restbus simulation, virtual bus simulation, or bus communication testing to name just a few.

dSPACE Solutions for Automotive Communication Systems

Since the bus and network ports are the main interfaces of the ECUs, it is nearly impossible to validate ECU functionality without bus simulation. Tests of ECU networks where not all necessary ECUs are available are called restbus simulation. Here, the simulator emulates the missing bus nodes.

dSPACE provides a complete set of tailored hardware and software to execute restbus simulations in a very convenient and efficient way throughout the entire development and testing process.

Rapid Prototyping

HIL Testing

Central Test Method for Validating ECUs

The dSPACE HIL test systems provide a simulated environment for efficient and reproducible validation of real ECUs in the laboratory 24/7. This increases test coverage and shortens validation times significantly. Our HIL solutions cover all vehicle domains from autonomous driving to zero emissions – starting with component testing and up to virtual vehicle testing.

SIL Testing

Software-in-the loop (SIL) testing with the powerful dSPACE solution for PC- and cloud-based simulation

With the dSPACE solution for software-in-the loop (SIL) testing, you can significantly accelerate your software development process by testing and validating virtually. dSPACE offers you a complete, modular, scalable development and test solution. You can conveniently simulate a device-under-test on a PC, connect it to physics-based models, run scalable tests in the cloud, and then easily reuse test scripts on hardware-in-the-loop (HIL) systems.

Supported Standards for Network Communication

- ARXML: Files describe systems according to AUTOSAR to describe different bus protocols, including the gateways.

- FIBEX: Fieldbus Exchange Format specified by ASAM containing information about the complete vehicle network.

- DBC: Communication database for CAN describing the communication between distributed ECUs.

- LDF: LIN description file specifying all the signals, data packages and scheduling tables of a LIN bus.

- SAEJ1939: Vehicle bus standard is based on CAN and used for communication and diagnostics among vehicle components

Development support from start to finish

Developing complex E/E systems and software with ever more safety-critical functions, especially in the area of autonomous systems, raises the question of guaranteeing function reliability. That's why dSPACE offers end-to-end expertise in functional safety, test strategy development as well as verification and validation in complex E/E processes - to support you from the earliest project stages to homologation.

dSPACE systems are easy to get up and running – however, if a project is more complex, if individual solutions are needed or if there is high time pressure, you can also trust dSPACE's fast, competent and reliable engineering services.