SCALEXIO

Modular real-time system

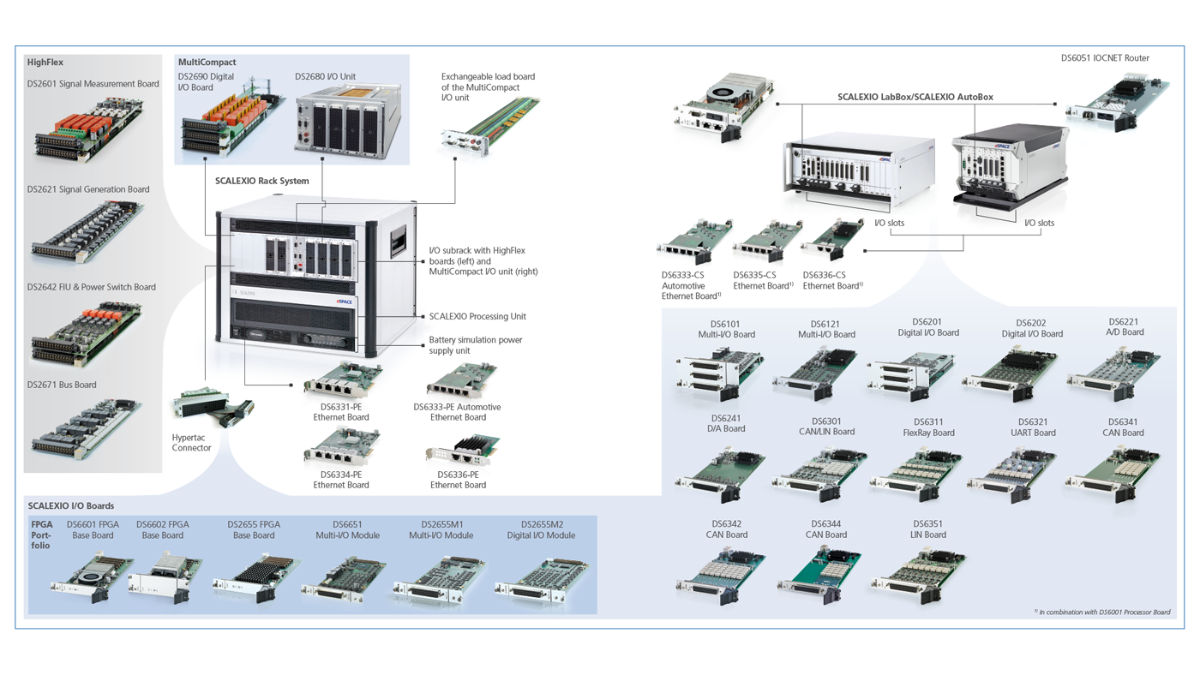

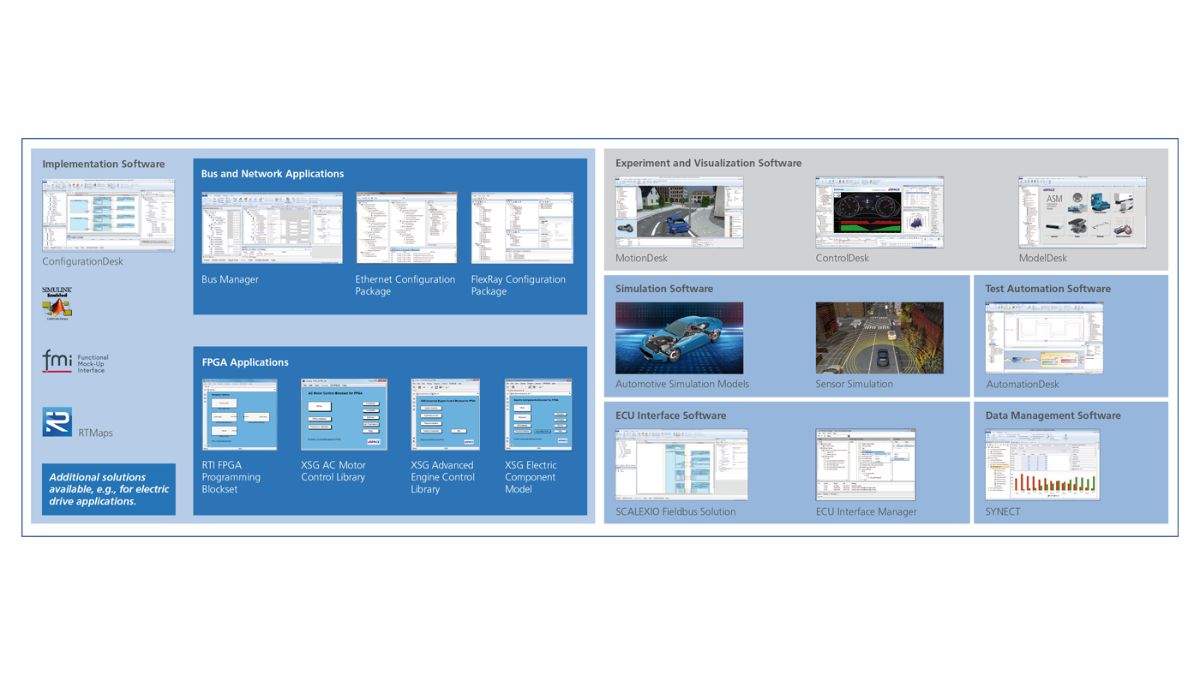

The modular dSPACE SCALEXIO system can be used for hardware-in-the-loop (HIL) and rapid control prototyping (RCP) applications. It is highly scalable, provides high-performance processor technology for demanding real-time requirements as well as comprehensive, precise, and fast I/O capabilities. SCALEXIO systems are configured in dSPACE ConfigurationDesk.

-

Your Choice of SCALEXIO Systems for Aerospace Applications

dSPACE has added a CompactPCI serial interface to its interface boards, giving users a wider choice of SCALEXIO systems.

-

DS6336-PE Ethernet Board

With the introduction of the new Ethernet board variant DS6336-CS, all SCALEXIO systems can now be equipped with Ethernet boards for fast data transmission to high-performance ECUs, e.g., for sensor simulation. Both interfaces of the DS6336 support the standard data rates of 100, 1,000, and 10,000 Mbit/s as well as 2.5 and 5 Gbit/s.

-

DS6651 Multi-I/O Module

New SCALEXIO FPGA I/O expansion for developing and testing highly dynamic control applications

-

High Voltage, Low Risk

Modern electric drives combine high power with perfect control, down to the microsecond. In the development of today’s drives, manufacturers depend on efficient platforms that release these high powers while ensuring operational reliability. To achieve this, JEE uses hardware-in-the-loop (HIL) testing with powerful software modeling and SCALEXIO hardware from dSPACE.

-

Powertrain Tests at the Push of a Button

To quickly and safely create model integration versions, for example, for testing new powertrains, HIL simulator farms can be equipped with workflow automation that is based on the dSPACE data management software SYNECT.

-

AI-in-the-Loop

The exciting new challenge developers faced was how to validate a vehicle whose control system makes independent decisions. ZF has met this challenge by combining traditional HIL technology with a sensor-realistic environment simulation. The test system designed for this purpose is based on the dSPACE tool chain.

-

Learning Connection Video: Lifecycle Traceability with SYNECT and codebeamer ALM

In this video, Intland and dSPACE demonstrate the direct integration of codebeamer in SYNECT. codebeamer and SYNECT users benefit from end-to-end traceability and a convenient way to plan and automate SIL and HIL validation tasks.

-

Universal Real-Time Platform

Published: dSPACE Magazine 2/2017, Dec 2017

Function developers of mechatronic systems from a wide range of industries are now entering the SCALEXIO era. Frank Mertens, lead product manager for rapid prototyping systems at dSPACE, explains what this is all about.

- High-performance processor and FPGA technology for the most demanding real-time requirements

- Comprehensive bus support and I/O capabilities

- Scalable system with various software-based configuration options

Application Areas

The dSPACE SCALEXIO product line comprises highly flexible and modular systems in several form factors for hardware-in-the-loop (HIL) and rapid control prototyping (RCP) applications for various industries such as automotive, automation, aerospace, medical, transportation, or research. Its powerful real-time technology and comprehensive bus support are ideally suited for the most demanding applications of today and tomorrow, which include highly automated and autonomous driving, electromobility, and increasing network communication driven by modern E/E architectures.

Key Benefits

- Scalable to any computation and I/O requirements

- For laboratory as well as in-vehicle applications

- High-performance processor technology for real-time calculation of large and complex simulation models

- Comprehensive, precise, and fast I/O capabilities based on FPGA technology

- IOCNET real-time backbone with very low jitter and high bandwidth for best-in-class closed-loop performance

- Openess for several third-party simulation environments via Functional Mock-up Interface (FMI) support

Two product types are available for the SCALEXIO processing hardware – the computing core: the SCALEXIO Processing Unit and the DS6001 Processor Board. Both hardware components are regularly updated to enable real-world testing.

SCALEXIO Processing Unit

- Real-time processing hardware for applications with high performance requirements

- Two product types:

- High core performance for applications that require strong computation performance per core

- High parallel performance for applications that require the parallel computation of very large simulation models

DS6001 Processor Board

- Real-time processing hardware for a very compact system size

- For applications that require fast closed-loop rates or high I/O bandwidth

The SCALEXIO I/O hardware provides a wide range of external interfaces. The hardware can be divided into four groups.

- Standard I/O hardware that covers development and testing of highly dynamic applications

- Programmable FPGA subsystems including various I/O modules for very fast, high-resolution signal-processing applications

- HighFlex boards, e.g., for ECU HIL tests including signal conditioning and fault simulation

- MultiCompact Units with a high number of I/O channels as well as integrated signal conditioning and onboard Failure Insertion Unit

All the SCALEXIO I/O hardware shares the following characteristics:

- Task-synchronous signal preprocessing on I/O boards to take some of the load off the real-time processor to ensure highest real-time performance of the SCALEXIO systems

- Connection to the processing hardware via an IOCNET interface

- Fully software-configurable

- Easy installation and configuration processes, so very little training effort is necessary

The SCALEXIO AutoBox brings the power of SCALEXIO into vehicles such as passenger cars, trucks, trains, and agricultural as well as construction machinery. Optimized for in-vehicle use, it is ideal for test drives when developing components such as electric powertrains and chassis control as well as functions for assisted, highly automated, and autonomous driving.

SCALEXIO LabBoxAs a laboratory system, the SCALEXIO LabBox is ideally suited for a wide range of applications, such as RCP, function testing, test bench control, and as a base system for customized HIL setups. The compact chassis fits on an office desk and offers space for up to 18 SCALEXIO I/O boards, which you can easily exchange in order to adapt the real-time system to various applications.

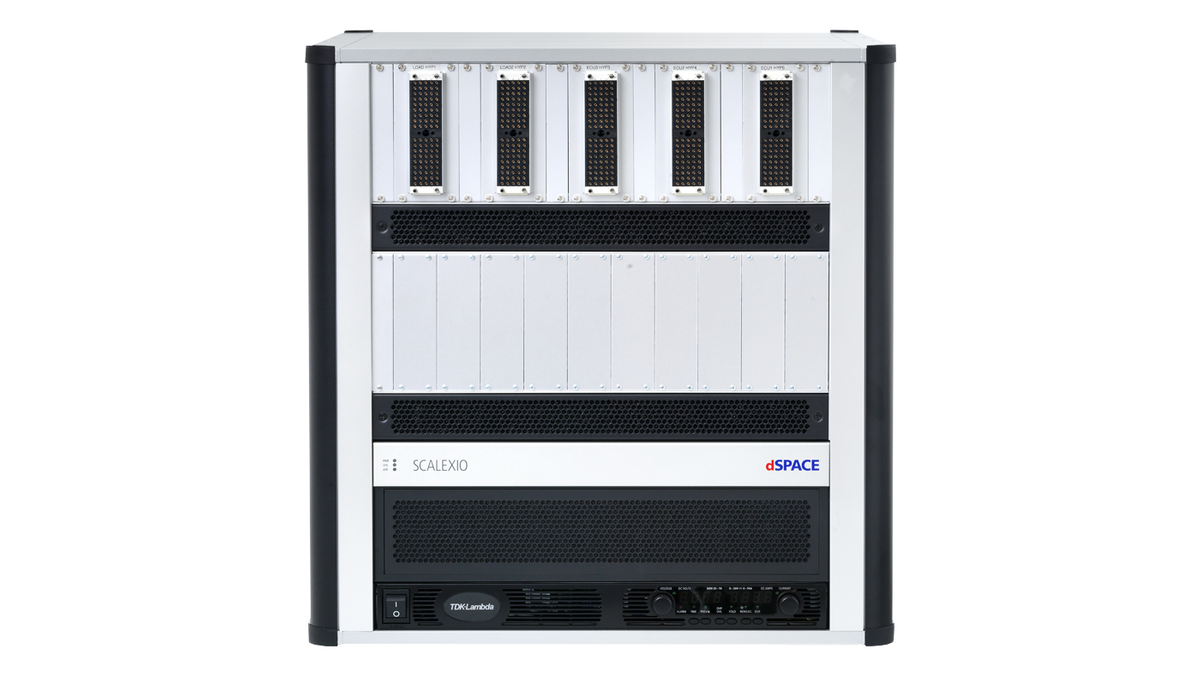

SCALEXIO Rack SystemFor ECU tests, the SCALEXIO off-the shelf rack systems pro-vide sufficient space for MultiCompact I/O units, HighFlex boards, and SCALEXIO I/O boards. In contrast to a SCALEXIO laboratory system, the SCALEXIO off-the-shelf system for HIL testing comprises onboard fault insertion and current measurement with comprehensive software support.

SCALEXIO Customized SystemThe customized SCALEXIO simulator is tailored to customer-specific requirements. It provides maximum flexibility and can be expanded easily. Its typical fields of application include complex tests of networked ECUs as well as tests that include electronic loads and complete virtual vehicles.

Mechanical Test BenchesdSPACE offers highly dynamic test benches for testing complex mechatronic systems. To achieve a realistic behavior of the components to be tested, the test bench uses real parts, such as an electric motor or mechanical loads. For motor controllers and power electronics control units for non-rotating applications, dSPACE also offers turn-key projects using electronic load modules that provide high voltages and hundreds of kVA.

Power HIL TestingOur power HIL systems close the gap between HIL and dynamometer testing. We offer ready-to-use solutions for testing any kind of inverter, including the controller and power electronics, at full power.

-

- View online

- Download

-

- View online

- Download

Drive innovation forward. Always on the pulse of technology development.

Subscribe to our expert knowledge. Learn from our successful project examples. Keep up to date on simulation and validation. Subscribe to/manage dSPACE direct and aerospace & defense now.